Prebaked Anodes for Aluminum Market Drivers, Trends, and Opportunities 2024-2032

View Full Report @ https://dataintelo.com/report/global-mono-block-hydraulic-manifold-market

The global Prebaked Anodes market for Aluminum production stood at USD 8.5 billion in 2023 and is projected to grow to USD 12.5 billion by 2032, reflecting a CAGR of 4.2%. The increasing demand for aluminum in industries such as aerospace, automotive, and construction is one of the key factors propelling this market growth. Additionally, innovations in prebaked anode manufacturing processes are playing a crucial role in supporting the expansion of the market.

The prebaked anodes for aluminum market is experiencing significant growth, driven by the increasing demand for aluminum across various industries, including automotive, aerospace, construction, and packaging. As a critical component in the aluminum production process, prebaked anodes play an indispensable role in ensuring efficiency and sustainability in the smelting process.

Market analysts at Dataintelo predict robust growth in the prebaked anodes market in the coming years, as manufacturers focus on enhancing anode performance and reducing environmental impact. This press release delves into key trends, growth drivers, and opportunities shaping the future of this vital market.

Request a Sample Report :- https://dataintelo.com/request-sample/495791?utm_source=dynamic&utm_medium=Bhushan

Understanding Prebaked Anodes and Their Role in Aluminum Production

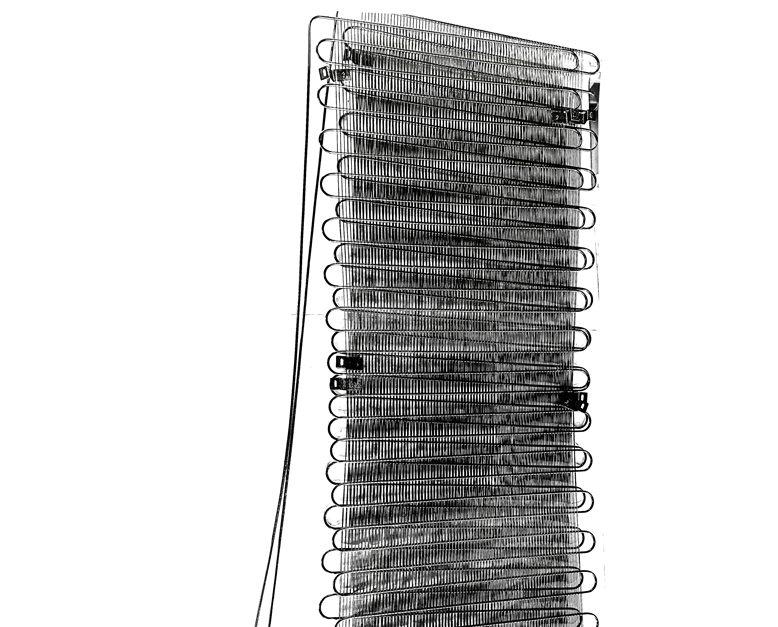

Prebaked anodes are carbon-based materials used in electrolytic aluminum production. These anodes, prepared using high-quality petroleum coke and coal tar pitch, provide the essential conductivity required in the Hall-Héroult process.

Given their critical role, the demand for high-quality prebaked anodes is increasing as aluminum producers seek to maximize efficiency while adhering to stricter environmental standards.

Key Market Drivers

Growing Aluminum Demand Across Industries

The global shift toward lightweight, durable, and recyclable materials is bolstering the demand for aluminum. Prebaked anodes, as a key input, are benefiting from this rising consumption trend.

Sustainability Initiatives

With sustainability taking center stage, aluminum smelters are adopting technologies and materials that reduce carbon emissions. The development of low-carbon prebaked anodes aligns with these initiatives, positioning the market for substantial growth.

Technological Advancements

Advances in prebaked anode manufacturing, such as optimized designs and improved raw material selection, are driving efficiency gains in aluminum production, further boosting market demand.

Urbanization and Infrastructure Development

Rapid urbanization, particularly in emerging economies, is fueling construction activities, increasing the demand for aluminum products, and consequently the prebaked anodes required for their production.

Enquire Before Buying :- https://dataintelo.com/enquiry-before-buying/495791?utm_source=dynamic&utm_medium=Bhushan

Regional Insights

The prebaked anodes market exhibits diverse growth patterns across regions:

Asia-Pacific: Dominates the global market, with China and India being the key contributors due to their large-scale aluminum production capacities.

North America and Europe: Witness steady demand, driven by established automotive and aerospace industries and growing focus on sustainable aluminum production.

Middle East and Africa: Emerging as promising regions, with investments in new smelters to cater to rising regional and global aluminum demand.

Opportunities in the Prebaked Anodes Market

The growing need for sustainable and cost-efficient solutions presents vast opportunities for manufacturers to innovate. Collaboration with aluminum producers to develop next-generation prebaked anodes with superior efficiency and reduced environmental footprint is expected to drive future growth.

Challenges and Competitive Landscape

While the market holds immense potential, it faces challenges such as:

Fluctuating raw material prices.

Stringent environmental regulations.

Competition from alternative materials and technologies.

The competitive landscape is marked by the presence of key players focusing on strategic collaborations, capacity expansions, and R&D investments to address these challenges and capitalize on growth opportunities.

Check Out the Report :- https://dataintelo.com/checkout/495791?utm_source=dynamic&utm_medium=Bhushan

Market Segmentation

The prebaked anodes market is segmented based on:

Raw Material: Petroleum coke, coal tar pitch, and others.

End-Use Industry: Automotive, aerospace, construction, packaging, and others.

Geography: North America, Europe, Asia-Pacific, Latin America, and Middle East & Africa.

Future Outlook

The market for prebaked anodes is poised to grow significantly as aluminum producers emphasize sustainability and operational efficiency. Emerging economies, advancements in anode manufacturing technologies, and growing investments in infrastructure development are likely to fuel this growth trajectory.

Access More Reports :-

Tip Up Furnaces Market Research Report 2032

https://dataintelo.com/report/global-tip-up-furnaces-market

Resin Flow Valve Market Research Report 2032

https://dataintelo.com/report/global-resin-flow-valve-market

Edge Trim Units Market Research Report 2032

https://dataintelo.com/report/global-edge-trim-units-market

Tugger Winches Market Research Report 2032

https://dataintelo.com/report/global-tugger-winches-market

Why Choose Dataintelo for Market Insights?

Dataintelo is committed to delivering actionable market intelligence that empowers businesses to stay ahead of the competition. Our in-depth research and analysis provide a 360-degree view of the market, ensuring our clients have the insights needed to make strategic decisions.

Conclusion

The global prebaked anodes market is on the brink of a transformative phase, driven by technological advancements, sustainability trends, and rising demand from key end-use industries. By staying informed and leveraging strategic insights, businesses can position themselves for success in this evolving market.

View Full Report @ https://dataintelo.com/report/global-mono-block-hydraulic-manifold-market

The global Prebaked Anodes market for Aluminum production stood at USD 8.5 billion in 2023 and is projected to grow to USD 12.5 billion by 2032, reflecting a CAGR of 4.2%. The increasing demand for aluminum in industries such as aerospace, automotive, and construction is one of the key factors propelling this market growth. Additionally, innovations in prebaked anode manufacturing processes are playing a crucial role in supporting the expansion of the market.

The prebaked anodes for aluminum market is experiencing significant growth, driven by the increasing demand for aluminum across various industries, including automotive, aerospace, construction, and packaging. As a critical component in the aluminum production process, prebaked anodes play an indispensable role in ensuring efficiency and sustainability in the smelting process.

Market analysts at Dataintelo predict robust growth in the prebaked anodes market in the coming years, as manufacturers focus on enhancing anode performance and reducing environmental impact. This press release delves into key trends, growth drivers, and opportunities shaping the future of this vital market.

Request a Sample Report :- https://dataintelo.com/request-sample/495791?utm_source=dynamic&utm_medium=Bhushan

Understanding Prebaked Anodes and Their Role in Aluminum Production

Prebaked anodes are carbon-based materials used in electrolytic aluminum production. These anodes, prepared using high-quality petroleum coke and coal tar pitch, provide the essential conductivity required in the Hall-Héroult process.

Given their critical role, the demand for high-quality prebaked anodes is increasing as aluminum producers seek to maximize efficiency while adhering to stricter environmental standards.

Key Market Drivers

Growing Aluminum Demand Across Industries

The global shift toward lightweight, durable, and recyclable materials is bolstering the demand for aluminum. Prebaked anodes, as a key input, are benefiting from this rising consumption trend.

Sustainability Initiatives

With sustainability taking center stage, aluminum smelters are adopting technologies and materials that reduce carbon emissions. The development of low-carbon prebaked anodes aligns with these initiatives, positioning the market for substantial growth.

Technological Advancements

Advances in prebaked anode manufacturing, such as optimized designs and improved raw material selection, are driving efficiency gains in aluminum production, further boosting market demand.

Urbanization and Infrastructure Development

Rapid urbanization, particularly in emerging economies, is fueling construction activities, increasing the demand for aluminum products, and consequently the prebaked anodes required for their production.

Enquire Before Buying :- https://dataintelo.com/enquiry-before-buying/495791?utm_source=dynamic&utm_medium=Bhushan

Regional Insights

The prebaked anodes market exhibits diverse growth patterns across regions:

Asia-Pacific: Dominates the global market, with China and India being the key contributors due to their large-scale aluminum production capacities.

North America and Europe: Witness steady demand, driven by established automotive and aerospace industries and growing focus on sustainable aluminum production.

Middle East and Africa: Emerging as promising regions, with investments in new smelters to cater to rising regional and global aluminum demand.

Opportunities in the Prebaked Anodes Market

The growing need for sustainable and cost-efficient solutions presents vast opportunities for manufacturers to innovate. Collaboration with aluminum producers to develop next-generation prebaked anodes with superior efficiency and reduced environmental footprint is expected to drive future growth.

Challenges and Competitive Landscape

While the market holds immense potential, it faces challenges such as:

Fluctuating raw material prices.

Stringent environmental regulations.

Competition from alternative materials and technologies.

The competitive landscape is marked by the presence of key players focusing on strategic collaborations, capacity expansions, and R&D investments to address these challenges and capitalize on growth opportunities.

Check Out the Report :- https://dataintelo.com/checkout/495791?utm_source=dynamic&utm_medium=Bhushan

Market Segmentation

The prebaked anodes market is segmented based on:

Raw Material: Petroleum coke, coal tar pitch, and others.

End-Use Industry: Automotive, aerospace, construction, packaging, and others.

Geography: North America, Europe, Asia-Pacific, Latin America, and Middle East & Africa.

Future Outlook

The market for prebaked anodes is poised to grow significantly as aluminum producers emphasize sustainability and operational efficiency. Emerging economies, advancements in anode manufacturing technologies, and growing investments in infrastructure development are likely to fuel this growth trajectory.

Access More Reports :-

Tip Up Furnaces Market Research Report 2032

https://dataintelo.com/report/global-tip-up-furnaces-market

Resin Flow Valve Market Research Report 2032

https://dataintelo.com/report/global-resin-flow-valve-market

Edge Trim Units Market Research Report 2032

https://dataintelo.com/report/global-edge-trim-units-market

Tugger Winches Market Research Report 2032

https://dataintelo.com/report/global-tugger-winches-market

Why Choose Dataintelo for Market Insights?

Dataintelo is committed to delivering actionable market intelligence that empowers businesses to stay ahead of the competition. Our in-depth research and analysis provide a 360-degree view of the market, ensuring our clients have the insights needed to make strategic decisions.

Conclusion

The global prebaked anodes market is on the brink of a transformative phase, driven by technological advancements, sustainability trends, and rising demand from key end-use industries. By staying informed and leveraging strategic insights, businesses can position themselves for success in this evolving market.

Prebaked Anodes for Aluminum Market Drivers, Trends, and Opportunities 2024-2032

View Full Report @ https://dataintelo.com/report/global-mono-block-hydraulic-manifold-market

The global Prebaked Anodes market for Aluminum production stood at USD 8.5 billion in 2023 and is projected to grow to USD 12.5 billion by 2032, reflecting a CAGR of 4.2%. The increasing demand for aluminum in industries such as aerospace, automotive, and construction is one of the key factors propelling this market growth. Additionally, innovations in prebaked anode manufacturing processes are playing a crucial role in supporting the expansion of the market.

The prebaked anodes for aluminum market is experiencing significant growth, driven by the increasing demand for aluminum across various industries, including automotive, aerospace, construction, and packaging. As a critical component in the aluminum production process, prebaked anodes play an indispensable role in ensuring efficiency and sustainability in the smelting process.

Market analysts at Dataintelo predict robust growth in the prebaked anodes market in the coming years, as manufacturers focus on enhancing anode performance and reducing environmental impact. This press release delves into key trends, growth drivers, and opportunities shaping the future of this vital market.

Request a Sample Report :- https://dataintelo.com/request-sample/495791?utm_source=dynamic&utm_medium=Bhushan

Understanding Prebaked Anodes and Their Role in Aluminum Production

Prebaked anodes are carbon-based materials used in electrolytic aluminum production. These anodes, prepared using high-quality petroleum coke and coal tar pitch, provide the essential conductivity required in the Hall-Héroult process.

Given their critical role, the demand for high-quality prebaked anodes is increasing as aluminum producers seek to maximize efficiency while adhering to stricter environmental standards.

Key Market Drivers

Growing Aluminum Demand Across Industries

The global shift toward lightweight, durable, and recyclable materials is bolstering the demand for aluminum. Prebaked anodes, as a key input, are benefiting from this rising consumption trend.

Sustainability Initiatives

With sustainability taking center stage, aluminum smelters are adopting technologies and materials that reduce carbon emissions. The development of low-carbon prebaked anodes aligns with these initiatives, positioning the market for substantial growth.

Technological Advancements

Advances in prebaked anode manufacturing, such as optimized designs and improved raw material selection, are driving efficiency gains in aluminum production, further boosting market demand.

Urbanization and Infrastructure Development

Rapid urbanization, particularly in emerging economies, is fueling construction activities, increasing the demand for aluminum products, and consequently the prebaked anodes required for their production.

Enquire Before Buying :- https://dataintelo.com/enquiry-before-buying/495791?utm_source=dynamic&utm_medium=Bhushan

Regional Insights

The prebaked anodes market exhibits diverse growth patterns across regions:

Asia-Pacific: Dominates the global market, with China and India being the key contributors due to their large-scale aluminum production capacities.

North America and Europe: Witness steady demand, driven by established automotive and aerospace industries and growing focus on sustainable aluminum production.

Middle East and Africa: Emerging as promising regions, with investments in new smelters to cater to rising regional and global aluminum demand.

Opportunities in the Prebaked Anodes Market

The growing need for sustainable and cost-efficient solutions presents vast opportunities for manufacturers to innovate. Collaboration with aluminum producers to develop next-generation prebaked anodes with superior efficiency and reduced environmental footprint is expected to drive future growth.

Challenges and Competitive Landscape

While the market holds immense potential, it faces challenges such as:

Fluctuating raw material prices.

Stringent environmental regulations.

Competition from alternative materials and technologies.

The competitive landscape is marked by the presence of key players focusing on strategic collaborations, capacity expansions, and R&D investments to address these challenges and capitalize on growth opportunities.

Check Out the Report :- https://dataintelo.com/checkout/495791?utm_source=dynamic&utm_medium=Bhushan

Market Segmentation

The prebaked anodes market is segmented based on:

Raw Material: Petroleum coke, coal tar pitch, and others.

End-Use Industry: Automotive, aerospace, construction, packaging, and others.

Geography: North America, Europe, Asia-Pacific, Latin America, and Middle East & Africa.

Future Outlook

The market for prebaked anodes is poised to grow significantly as aluminum producers emphasize sustainability and operational efficiency. Emerging economies, advancements in anode manufacturing technologies, and growing investments in infrastructure development are likely to fuel this growth trajectory.

Access More Reports :-

Tip Up Furnaces Market Research Report 2032

https://dataintelo.com/report/global-tip-up-furnaces-market

Resin Flow Valve Market Research Report 2032

https://dataintelo.com/report/global-resin-flow-valve-market

Edge Trim Units Market Research Report 2032

https://dataintelo.com/report/global-edge-trim-units-market

Tugger Winches Market Research Report 2032

https://dataintelo.com/report/global-tugger-winches-market

Why Choose Dataintelo for Market Insights?

Dataintelo is committed to delivering actionable market intelligence that empowers businesses to stay ahead of the competition. Our in-depth research and analysis provide a 360-degree view of the market, ensuring our clients have the insights needed to make strategic decisions.

Conclusion

The global prebaked anodes market is on the brink of a transformative phase, driven by technological advancements, sustainability trends, and rising demand from key end-use industries. By staying informed and leveraging strategic insights, businesses can position themselves for success in this evolving market.

0 Comments

0 Shares

0 Reviews