Advantages and application fields of wire-tube condenser

Wire-tube condenser is a common heat exchanger widely used in various fields. Its design structure and choice of materials give it a number of advantages that make it ideal for use in many industrial and commercial applications.

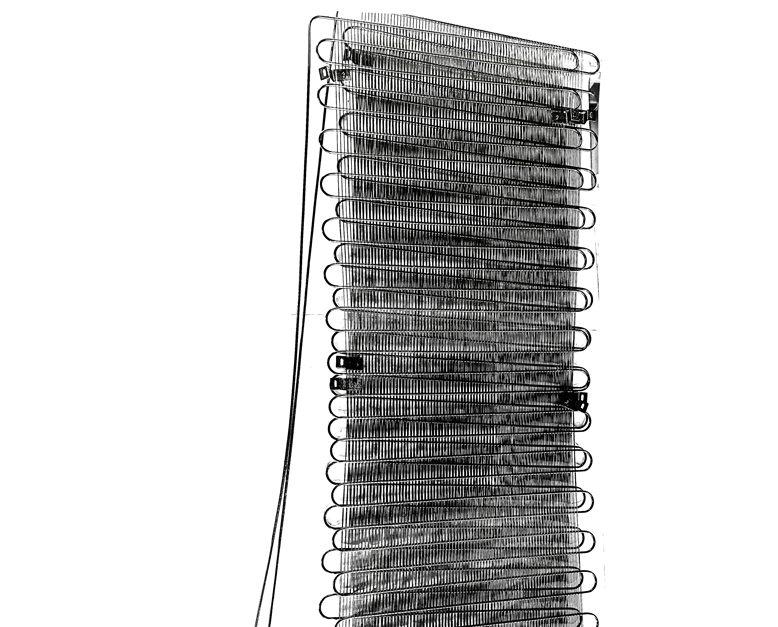

wire-tube condenser

First, the wire-tube condenser has efficient heat conduction capabilities. Its design structure allows heat to be quickly transferred to the cooling medium, thereby improving the efficiency of heat exchange. Its internal pipes and external wire mesh form a complex heat conduction path, which enables the heat to be fully utilized and dissipated quickly. This high-efficiency heat transfer capability enables the wire-tube condenser to operate stably under many high-temperature and high-pressure conditions.

Second, the wire-tube condenser has a smaller volume and weight. Compared with other types of heat exchangers, the wire-tube condenser has a more compact design and takes up less space. This makes it more effective where space is limited. At the same time, due to the use of lightweight materials, the weight of the entire device is relatively light, which is convenient for installation and maintenance.

In addition, the wire-tube condenser also has high corrosion resistance and pressure resistance. Its outer wire mesh is usually made of corrosion-resistant materials such as stainless steel, which can effectively resist oxidation and corrosion. The internal pipeline can also choose the appropriate material according to the specific working conditions to ensure that it can withstand the work under a high-pressure environment. This corrosion resistance and pressure resistance make wire-tube condensers widely used in chemical, petroleum, pharmaceutical, and other fields.

In terms of application fields, the wire-tube condenser is widely used in many industrial and commercial fields. First, it is commonly used in air conditioning and refrigeration equipment. Air-conditioning and refrigeration equipment need to conduct indoor heat to the outside through a heat exchanger, and a wire-tube condenser can provide an efficient heat exchange effect so that air-conditioning and refrigeration equipment can quickly cool down.

Secondly, wire-tube condenser is also commonly used in chemical and petroleum industries. In these industries, many processes require heat exchange, and the wire-tube condenser can provide a stable heat transfer effect to meet the requirements of the process. At the same time, its corrosion resistance and pressure resistance also enable it to operate stably for a long time in harsh working environments.

In addition, wire-tube condensers are often used in the food processing and pharmaceutical industries. In these industries, many processes need to be sterilized and cooled, and wire-tube condensers can provide an efficient heat exchange effect to ensure product quality and safety.

In a word, wire-tube condenser, as an efficient, compact, corrosion-resistant and pressure-resistant heat exchanger, is widely used in various fields. Its advantages lie in efficient heat transfer capability, small size and weight, and good corrosion resistance and pressure resistance. In air conditioning, refrigeration, chemical industry, petroleum, food processing, and pharmaceutical industries, it can play an important role and meet the needs of various processes.

How to choose the right wire tube condenser?

Different types of wire tube condensers

How to choose a refrigeration wire tube condenser?

https://www.ningbo-senjun.com/Advantages-and-application-fields-of-wire-tube-condenser.html

Wire-tube condenser is a common heat exchanger widely used in various fields. Its design structure and choice of materials give it a number of advantages that make it ideal for use in many industrial and commercial applications.

wire-tube condenser

First, the wire-tube condenser has efficient heat conduction capabilities. Its design structure allows heat to be quickly transferred to the cooling medium, thereby improving the efficiency of heat exchange. Its internal pipes and external wire mesh form a complex heat conduction path, which enables the heat to be fully utilized and dissipated quickly. This high-efficiency heat transfer capability enables the wire-tube condenser to operate stably under many high-temperature and high-pressure conditions.

Second, the wire-tube condenser has a smaller volume and weight. Compared with other types of heat exchangers, the wire-tube condenser has a more compact design and takes up less space. This makes it more effective where space is limited. At the same time, due to the use of lightweight materials, the weight of the entire device is relatively light, which is convenient for installation and maintenance.

In addition, the wire-tube condenser also has high corrosion resistance and pressure resistance. Its outer wire mesh is usually made of corrosion-resistant materials such as stainless steel, which can effectively resist oxidation and corrosion. The internal pipeline can also choose the appropriate material according to the specific working conditions to ensure that it can withstand the work under a high-pressure environment. This corrosion resistance and pressure resistance make wire-tube condensers widely used in chemical, petroleum, pharmaceutical, and other fields.

In terms of application fields, the wire-tube condenser is widely used in many industrial and commercial fields. First, it is commonly used in air conditioning and refrigeration equipment. Air-conditioning and refrigeration equipment need to conduct indoor heat to the outside through a heat exchanger, and a wire-tube condenser can provide an efficient heat exchange effect so that air-conditioning and refrigeration equipment can quickly cool down.

Secondly, wire-tube condenser is also commonly used in chemical and petroleum industries. In these industries, many processes require heat exchange, and the wire-tube condenser can provide a stable heat transfer effect to meet the requirements of the process. At the same time, its corrosion resistance and pressure resistance also enable it to operate stably for a long time in harsh working environments.

In addition, wire-tube condensers are often used in the food processing and pharmaceutical industries. In these industries, many processes need to be sterilized and cooled, and wire-tube condensers can provide an efficient heat exchange effect to ensure product quality and safety.

In a word, wire-tube condenser, as an efficient, compact, corrosion-resistant and pressure-resistant heat exchanger, is widely used in various fields. Its advantages lie in efficient heat transfer capability, small size and weight, and good corrosion resistance and pressure resistance. In air conditioning, refrigeration, chemical industry, petroleum, food processing, and pharmaceutical industries, it can play an important role and meet the needs of various processes.

How to choose the right wire tube condenser?

Different types of wire tube condensers

How to choose a refrigeration wire tube condenser?

https://www.ningbo-senjun.com/Advantages-and-application-fields-of-wire-tube-condenser.html

Advantages and application fields of wire-tube condenser

Wire-tube condenser is a common heat exchanger widely used in various fields. Its design structure and choice of materials give it a number of advantages that make it ideal for use in many industrial and commercial applications.

wire-tube condenser

First, the wire-tube condenser has efficient heat conduction capabilities. Its design structure allows heat to be quickly transferred to the cooling medium, thereby improving the efficiency of heat exchange. Its internal pipes and external wire mesh form a complex heat conduction path, which enables the heat to be fully utilized and dissipated quickly. This high-efficiency heat transfer capability enables the wire-tube condenser to operate stably under many high-temperature and high-pressure conditions.

Second, the wire-tube condenser has a smaller volume and weight. Compared with other types of heat exchangers, the wire-tube condenser has a more compact design and takes up less space. This makes it more effective where space is limited. At the same time, due to the use of lightweight materials, the weight of the entire device is relatively light, which is convenient for installation and maintenance.

In addition, the wire-tube condenser also has high corrosion resistance and pressure resistance. Its outer wire mesh is usually made of corrosion-resistant materials such as stainless steel, which can effectively resist oxidation and corrosion. The internal pipeline can also choose the appropriate material according to the specific working conditions to ensure that it can withstand the work under a high-pressure environment. This corrosion resistance and pressure resistance make wire-tube condensers widely used in chemical, petroleum, pharmaceutical, and other fields.

In terms of application fields, the wire-tube condenser is widely used in many industrial and commercial fields. First, it is commonly used in air conditioning and refrigeration equipment. Air-conditioning and refrigeration equipment need to conduct indoor heat to the outside through a heat exchanger, and a wire-tube condenser can provide an efficient heat exchange effect so that air-conditioning and refrigeration equipment can quickly cool down.

Secondly, wire-tube condenser is also commonly used in chemical and petroleum industries. In these industries, many processes require heat exchange, and the wire-tube condenser can provide a stable heat transfer effect to meet the requirements of the process. At the same time, its corrosion resistance and pressure resistance also enable it to operate stably for a long time in harsh working environments.

In addition, wire-tube condensers are often used in the food processing and pharmaceutical industries. In these industries, many processes need to be sterilized and cooled, and wire-tube condensers can provide an efficient heat exchange effect to ensure product quality and safety.

In a word, wire-tube condenser, as an efficient, compact, corrosion-resistant and pressure-resistant heat exchanger, is widely used in various fields. Its advantages lie in efficient heat transfer capability, small size and weight, and good corrosion resistance and pressure resistance. In air conditioning, refrigeration, chemical industry, petroleum, food processing, and pharmaceutical industries, it can play an important role and meet the needs of various processes.

How to choose the right wire tube condenser?

Different types of wire tube condensers

How to choose a refrigeration wire tube condenser?

https://www.ningbo-senjun.com/Advantages-and-application-fields-of-wire-tube-condenser.html

0 Comments

0 Shares

0 Reviews