🥰How does a #crawler_water_well_drilling_rig work?

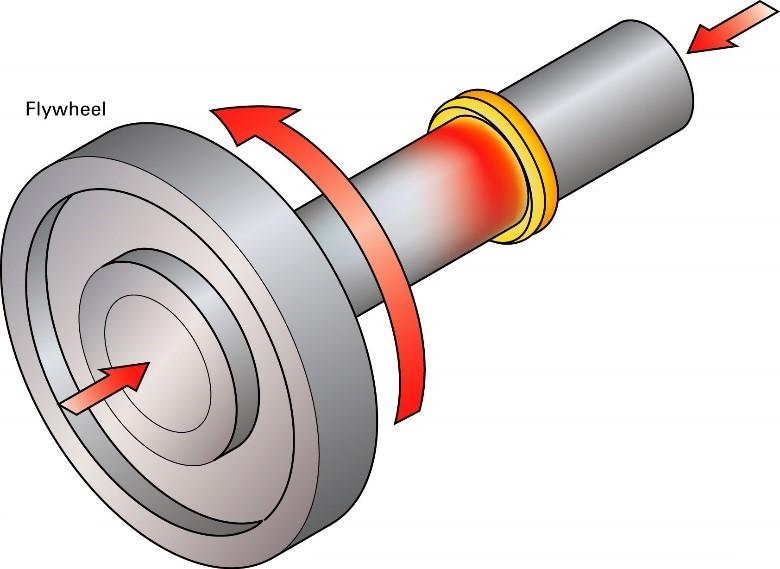

🤩The power machine passes the clutch, drive shaft and gearbox in turn to transfer the power to the rotator of the #drilling_rig, and then the rotator passes the rotary motion of the rotator to the active drill rod of the drilling rig through the vertical shaft sleeve, thus driving the rotation of the drilling tool; the drilling tool relies on the feeding cylinder on the rotator and its own gravity to realize its #drilling work through the control of the manipulation valve.👍

🥳If you are interested in #water_well_drilling_rigs,welcome to contact us directly:

👉Website: 𝐡𝐭𝐭𝐩𝐬://𝐰𝐰𝐰.𝐮𝐧𝐢𝐪𝐮𝐞𝐝𝐫𝐢𝐥𝐥𝐢𝐧𝐠-𝐭𝐞𝐜𝐡.𝐜𝐨𝐦

👉Whatsapp:+𝟖𝟔 𝟏𝟓𝟖 𝟗𝟎𝟔𝟎 𝟗𝟎𝟑𝟏/+𝟔𝟑 𝟗𝟎𝟔𝟒 𝟓𝟓𝟐 𝟕𝟏𝟐

👉Email: 𝐬𝐚𝐥𝐞𝐬𝟏𝟕@𝐮𝐧𝐢𝐪𝐮𝐞-𝐜𝐨𝐧𝐬.𝐜𝐨𝐦

#drillingrig #waterdrillingrig #waterwelldrillingrig #dieseldrillingrig

#mobiledrillingrig #minidrillingrig #Unnique_Group

🤩The power machine passes the clutch, drive shaft and gearbox in turn to transfer the power to the rotator of the #drilling_rig, and then the rotator passes the rotary motion of the rotator to the active drill rod of the drilling rig through the vertical shaft sleeve, thus driving the rotation of the drilling tool; the drilling tool relies on the feeding cylinder on the rotator and its own gravity to realize its #drilling work through the control of the manipulation valve.👍

🥳If you are interested in #water_well_drilling_rigs,welcome to contact us directly:

👉Website: 𝐡𝐭𝐭𝐩𝐬://𝐰𝐰𝐰.𝐮𝐧𝐢𝐪𝐮𝐞𝐝𝐫𝐢𝐥𝐥𝐢𝐧𝐠-𝐭𝐞𝐜𝐡.𝐜𝐨𝐦

👉Whatsapp:+𝟖𝟔 𝟏𝟓𝟖 𝟗𝟎𝟔𝟎 𝟗𝟎𝟑𝟏/+𝟔𝟑 𝟗𝟎𝟔𝟒 𝟓𝟓𝟐 𝟕𝟏𝟐

👉Email: 𝐬𝐚𝐥𝐞𝐬𝟏𝟕@𝐮𝐧𝐢𝐪𝐮𝐞-𝐜𝐨𝐧𝐬.𝐜𝐨𝐦

#drillingrig #waterdrillingrig #waterwelldrillingrig #dieseldrillingrig

#mobiledrillingrig #minidrillingrig #Unnique_Group

🥰How does a #crawler_water_well_drilling_rig work?

🤩The power machine passes the clutch, drive shaft and gearbox in turn to transfer the power to the rotator of the #drilling_rig, and then the rotator passes the rotary motion of the rotator to the active drill rod of the drilling rig through the vertical shaft sleeve, thus driving the rotation of the drilling tool; the drilling tool relies on the feeding cylinder on the rotator and its own gravity to realize its #drilling work through the control of the manipulation valve.👍

🥳If you are interested in #water_well_drilling_rigs,welcome to contact us directly:

👉Website: 𝐡𝐭𝐭𝐩𝐬://𝐰𝐰𝐰.𝐮𝐧𝐢𝐪𝐮𝐞𝐝𝐫𝐢𝐥𝐥𝐢𝐧𝐠-𝐭𝐞𝐜𝐡.𝐜𝐨𝐦

👉Whatsapp:+𝟖𝟔 𝟏𝟓𝟖 𝟗𝟎𝟔𝟎 𝟗𝟎𝟑𝟏/+𝟔𝟑 𝟗𝟎𝟔𝟒 𝟓𝟓𝟐 𝟕𝟏𝟐

👉Email: 𝐬𝐚𝐥𝐞𝐬𝟏𝟕@𝐮𝐧𝐢𝐪𝐮𝐞-𝐜𝐨𝐧𝐬.𝐜𝐨𝐦

#drillingrig #waterdrillingrig #waterwelldrillingrig #dieseldrillingrig

#mobiledrillingrig #minidrillingrig #Unnique_Group

0 Commentaires

0 Parts

0 Aperçu