Concrete Paver Machine for Sale: How It Works and Operational Tips

Concrete paver machines are essential equipment in modern road construction, highway projects, and urban infrastructure development. Designed to lay concrete with precision, efficiency, and uniformity, these machines have transformed how pavements, highways, and industrial floors are built. For companies looking to invest in a concrete paver machine for sale (

https://aimixgroup.com/concrete-paving-machine/

), understanding how the machine works and implementing proper operational tips is critical to maximize performance, durability, and return on investment.

1. Overview of a Concrete Paver Machine

A concrete paver machine is a self-propelled device that spreads, shapes, and partially compacts fresh concrete into pavements. It eliminates the need for manual spreading and leveling, which not only speeds up construction but also ensures consistent surface quality.

Modern concrete paver machines vary in size and capacity, from compact models suitable for small urban projects to large-scale machines used in highways and industrial flooring. Key components typically include:

Hopper: Receives concrete from a mixer or truck and supplies it to the spreading system.

Conveyor system: Transfers concrete from the hopper to the screed evenly.

Screed: Levels, partially compacts, and smooths the concrete surface.

Crawler tracks or wheels: Enable mobility and allow the machine to move along the paving path.

Control system: Operator interface for adjusting speed, screed vibration, and paving thickness.

2. How a Concrete Paver Machine Works

The working process of a concrete paver machine involves several coordinated steps:

Concrete Feeding: Fresh concrete is delivered into the hopper, either from a ready mix truck or a concrete pump. It is crucial to maintain a consistent feed to prevent interruptions and ensure uniform paving.

Conveying: The machine’s conveyor system distributes the concrete evenly across the width of the screed. Chain conveyors or auger systems are commonly used for this purpose.

Spreading and Leveling: The screed spreads the concrete to the desired thickness and width. Adjustable extensions allow customization for different road widths or pavement designs.

Initial Compaction: Vibration mechanisms within the screed provide preliminary compaction, reducing air pockets and enhancing surface strength.

Finishing: The operator controls the screed and additional finishing attachments, such as trowels or mats, to achieve a smooth, uniform concrete surface.

3. Operational Tips for Optimal Performance

Proper operation is crucial for achieving high-quality pavement and maximizing the lifespan of a concrete paver machine. Here are some essential tips:

a. Pre-Operational Inspection

Before starting, check the machine’s mechanical systems, including the conveyor, screed, tracks, and hydraulic components. Inspect the electrical system and control panels to ensure proper functionality.

b. Maintain Consistent Concrete Supply

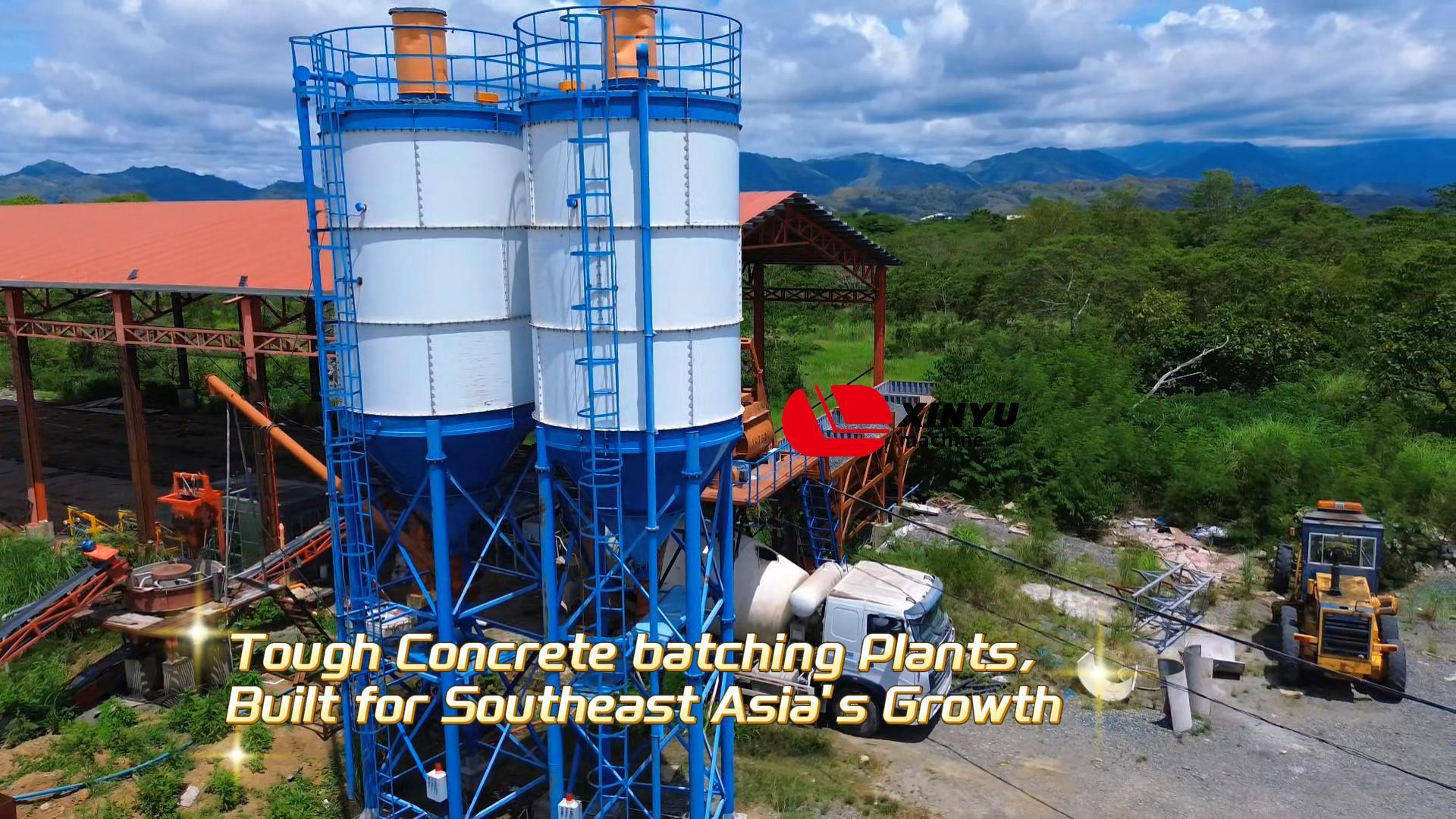

Uneven concrete supply can lead to surface defects or machine overload. Coordinate with concrete suppliers or batching plants to maintain a steady feed. For long paving runs, using a ready mix concrete batching plant near the site can improve efficiency and reduce material handling delays.

c. Adjust Screed Settings Properly

Screed height, vibration, and heating (if equipped) should be set according to the concrete mix, weather conditions, and project requirements. Improper settings can cause uneven surfaces, segregation, or premature cracking.

d. Control Machine Speed

The paving speed should match the concrete placement rate and the compaction process. Moving too fast can result in uneven thickness, while moving too slow may cause concrete to stiffen before proper leveling.

e. Monitor Environmental Conditions

High temperatures, wind, or rain can affect concrete workability and curing. Adjust water content, screed temperature, or paving schedule to maintain surface quality.

f. Regular Maintenance

Routine maintenance is vital for long-term reliability. Clean the hopper, conveyor, and screed after each use to prevent hardened concrete buildup. Lubricate moving parts, check hydraulic fluids, and inspect tracks or tires regularly.

4. Benefits of Using a Concrete Paver Machine

Investing in a concrete paver machine for sale offers several advantages:

Efficiency: Speeds up paving operations, reducing labor costs and project timelines.

Precision: Ensures uniform thickness, width, and surface finish.

Safety: Minimizes manual handling of concrete, reducing operator fatigue and injury risks.

Versatility: Suitable for roads, highways, airport runways, industrial floors, and decorative pavements.

5. Choosing the Right Concrete Paver Machine

When selecting a concrete paver machine for sale, consider the following factors:

Paving Width and Thickness: Match the machine’s capacity with the project requirements.

Mobility: Crawler tracks are ideal for rough terrain, while wheeled models are suitable for paved surfaces.

Automation Features: Advanced machines offer programmable controls for speed, vibration, and screed settings.

Supplier Support: Reputable suppliers provide training, spare parts, and technical assistance, ensuring smooth operation.

6. Conclusion

A concrete paver machine is a game-changer in modern construction, enabling faster, safer, and more precise concrete paving. Understanding how it works and following operational best practices are critical for achieving consistent, high-quality pavements. From pre-operation checks to proper maintenance, every step contributes to maximizing efficiency and prolonging the machine’s service life.

For companies considering investment, working with reliable suppliers ensures access to advanced features, training, and ongoing support, making the purchase of a concrete paver machine for sale a strategic decision for long-term project success.

Concrete Paver Machine for Sale: How It Works and Operational Tips

Concrete paver machines are essential equipment in modern road construction, highway projects, and urban infrastructure development. Designed to lay concrete with precision, efficiency, and uniformity, these machines have transformed how pavements, highways, and industrial floors are built. For companies looking to invest in a concrete paver machine for sale (https://aimixgroup.com/concrete-paving-machine/

), understanding how the machine works and implementing proper operational tips is critical to maximize performance, durability, and return on investment.

1. Overview of a Concrete Paver Machine

A concrete paver machine is a self-propelled device that spreads, shapes, and partially compacts fresh concrete into pavements. It eliminates the need for manual spreading and leveling, which not only speeds up construction but also ensures consistent surface quality.

Modern concrete paver machines vary in size and capacity, from compact models suitable for small urban projects to large-scale machines used in highways and industrial flooring. Key components typically include:

Hopper: Receives concrete from a mixer or truck and supplies it to the spreading system.

Conveyor system: Transfers concrete from the hopper to the screed evenly.

Screed: Levels, partially compacts, and smooths the concrete surface.

Crawler tracks or wheels: Enable mobility and allow the machine to move along the paving path.

Control system: Operator interface for adjusting speed, screed vibration, and paving thickness.

2. How a Concrete Paver Machine Works

The working process of a concrete paver machine involves several coordinated steps:

Concrete Feeding: Fresh concrete is delivered into the hopper, either from a ready mix truck or a concrete pump. It is crucial to maintain a consistent feed to prevent interruptions and ensure uniform paving.

Conveying: The machine’s conveyor system distributes the concrete evenly across the width of the screed. Chain conveyors or auger systems are commonly used for this purpose.

Spreading and Leveling: The screed spreads the concrete to the desired thickness and width. Adjustable extensions allow customization for different road widths or pavement designs.

Initial Compaction: Vibration mechanisms within the screed provide preliminary compaction, reducing air pockets and enhancing surface strength.

Finishing: The operator controls the screed and additional finishing attachments, such as trowels or mats, to achieve a smooth, uniform concrete surface.

3. Operational Tips for Optimal Performance

Proper operation is crucial for achieving high-quality pavement and maximizing the lifespan of a concrete paver machine. Here are some essential tips:

a. Pre-Operational Inspection

Before starting, check the machine’s mechanical systems, including the conveyor, screed, tracks, and hydraulic components. Inspect the electrical system and control panels to ensure proper functionality.

b. Maintain Consistent Concrete Supply

Uneven concrete supply can lead to surface defects or machine overload. Coordinate with concrete suppliers or batching plants to maintain a steady feed. For long paving runs, using a ready mix concrete batching plant near the site can improve efficiency and reduce material handling delays.

c. Adjust Screed Settings Properly

Screed height, vibration, and heating (if equipped) should be set according to the concrete mix, weather conditions, and project requirements. Improper settings can cause uneven surfaces, segregation, or premature cracking.

d. Control Machine Speed

The paving speed should match the concrete placement rate and the compaction process. Moving too fast can result in uneven thickness, while moving too slow may cause concrete to stiffen before proper leveling.

e. Monitor Environmental Conditions

High temperatures, wind, or rain can affect concrete workability and curing. Adjust water content, screed temperature, or paving schedule to maintain surface quality.

f. Regular Maintenance

Routine maintenance is vital for long-term reliability. Clean the hopper, conveyor, and screed after each use to prevent hardened concrete buildup. Lubricate moving parts, check hydraulic fluids, and inspect tracks or tires regularly.

4. Benefits of Using a Concrete Paver Machine

Investing in a concrete paver machine for sale offers several advantages:

Efficiency: Speeds up paving operations, reducing labor costs and project timelines.

Precision: Ensures uniform thickness, width, and surface finish.

Safety: Minimizes manual handling of concrete, reducing operator fatigue and injury risks.

Versatility: Suitable for roads, highways, airport runways, industrial floors, and decorative pavements.

5. Choosing the Right Concrete Paver Machine

When selecting a concrete paver machine for sale, consider the following factors:

Paving Width and Thickness: Match the machine’s capacity with the project requirements.

Mobility: Crawler tracks are ideal for rough terrain, while wheeled models are suitable for paved surfaces.

Automation Features: Advanced machines offer programmable controls for speed, vibration, and screed settings.

Supplier Support: Reputable suppliers provide training, spare parts, and technical assistance, ensuring smooth operation.

6. Conclusion

A concrete paver machine is a game-changer in modern construction, enabling faster, safer, and more precise concrete paving. Understanding how it works and following operational best practices are critical for achieving consistent, high-quality pavements. From pre-operation checks to proper maintenance, every step contributes to maximizing efficiency and prolonging the machine’s service life.

For companies considering investment, working with reliable suppliers ensures access to advanced features, training, and ongoing support, making the purchase of a concrete paver machine for sale a strategic decision for long-term project success.