Company Profile

Zhonghai SAN LING Elevator (Suzhou) Co., Ltd. is located in the most developed Yangtze River Delta region of China's economy. It is located in Suzhou, Jiangsu, a beautiful and rich Jiangnan city. It is a modern professional elevator company that integrates the R & D, design, manufacturing, sales, installation and maintenance of ladder.

The company has a modern plant with an area of more than 40,000 square meters and an office area of more than 20,000 square meters. It has a 68 -meter -high elevator test tower, and various high -precision production and testing are introduced from the United States, Japan, Belgium and other countries. Equipment, realize large -scale and beneficial precision production models, with an annual production capacity of more than 5,000 units.

Since its establishment, Zhonghai Mitsubishi Elevator has adhered to technology as the fulcrum, market -oriented, and continuously developing various energy -saving and environmentally friendly quality elevator products, and is committed to providing customers with a safer and more comfortable one -stop elevator solution. The company's product system covers passengers, cargo, sightseeing, escalators and automatic humanity. The ladder is perfect and complete. The company has a national special equipment manufacturing A -level license qualification and installation and reconstruction A -level license qualification. It has passed the ISO9001 quality management system certification, ISO14001 environmental management system certification, and OHSAS18000 occupational health and safety management system certification. It is also certified by the CE of the German TUV demonstration agency. It is an A -level enterprise recognized by the State Administration for Industry and Commerce and a prestigious enterprise in Jiangsu Province.

Based on the latest domestic and international standards, the company has formulated a strict quality management system. All factory products have passed rigorous inspection. The quality is excellent and excellent. In addition, the company has established its own new product development institution, and has a leading position in the industry in the high -speed elevator field and energy conservation and environmental protection. With continuous innovation technology, first -class talent team, and perfect after -sales service standards, the company has won a good reputation in domestic and international, developing a broad market, and its products are exported to many countries and regions at home and abroad.

Zhonghai san ling Elevator has meticulous work and eternal integrity. In the next five years, Zhonghai Mitsubishi Elevator will always be committed to creating a well -known international brand enterprise with globalization, and continue to insist on integrating integrity, responsibility, dedication, and cooperation as the core values of the company's long -term development. Enterprise spirit, adhere to the business philosophy of integrity operations, continuous progress, and win -win cooperation, and run the corporate service concept of customer first and excellent services to every aspect of China Shippeed Mitsubishi production, sales and after -sales service, and provide customers with green, environmental protection, no no Worry -type integrated vertical traffic solutions provide infinitely upward personalized carrier experience for various buildings.

Avenue, Ling Yun straight up

1977

Japan Mitsubishi Electric Corporation developed a gear-free catering elevator controlled by Lored, controlled by Lored.

1983

Mitsubishi Electric Company developed the world's first transformer transformer -driven elevator.

1985

Mitsubishi Motor Company developed a spiral escalator operating curve and successfully put into production. Spiral escalator can save architectural space and have decorative art effects.

1990

Mitsubishi Electric Company used the variable frequency drive system for hydraulic elevator for the first time.

1991

Mitsubishi Electric Corporation developed a large upgrade height escalator with an intermediate horizontal section. This multi -sloping escalator can reduce passengers' fear of height when a large increase in height, and can coordinate configuration with the building structure of the building.

1993

Mitsubishi Electric installed a 12.50m/S -speed ultra -high -speed passenger elevator at the LANDMARK Building in Yokohama, Japan. It was the fastest passenger elevator at that time at that time. Ultra -high -speed elevators are often used in TV towers, ultra -high buildings and other significant buildings.

1996

Mitsubishi Motor Company developed a double -layer high -speed elevator with a permanent magnet motor without gear traction machine and a dual -disc braking system, which was installed in the MORI building in Shanghai.

From April 17th to 20th, 2002, Mitsubishi Motor Corporation exhibited an automatic escalator model for high -speed operation at the 5th China International Elevator Exhibition. Pangic telescopic driving rack structures can change the interval between the steps during runtime, thereby changing the speed. The speed of its tilt section is 1.5 times that of the speed of the entrance and exit level, which not only shortens the passenger's ladder time, but also improves the safety and stability of the escalator on the escalator.

Zhonghai SAN LING Elevator (Suzhou) Co., Ltd.锛圱he registered capital is 108 million yuan锛夛紝It is a modern elevator company that was co -founded by the national high -tech enterprise Suzhou Sueling Elevator Co., Ltd. and Macau Zhonghai Mitsubishi Elevator Investment Co., Ltd. and the introduction of scientific and technological achievements jointly founded锛孴he design, development, manufacturing, sales, installation, and maintenance of modern professional elevator companies established on January 3, 2017. The product covers a variety of elevator categories, including passenger elevators, sightseeing elevators, medical elevators, debris elevators, escalators, and automatic sidewalk products. It has the A -level qualification of elevator manufacturing, installation, transformation and maintenance issued by the State Administration of Quality Supervision and Inspection Essence.

Zhonghai sanling Elevator adheres to the corporate spirit of "honoring sincerity, Yu Gathering in Germany, high -efficiency, and innovative quality", and has built a modern elevator manufacturing base that integrates design, development, manufacturing, sales, installation, and maintenance. The perfect after -sales service network provides reliable vertical transportation for the upward development of global cities.

Zhonghai Sanling category diverse

As a domestic professional elevator manufacturing enterprise, China Shipping Mitsubishi uses the high standards of Industry 4.0, exclusive research and development and production of multiple elevator series products, covering passenger elevators, sightseeing elevators, medical elevators, cargo carries, miscellaneous elevators, escalators, automatic sidewalk products Waiting for multi -category elevators can provide a comprehensive security transformation solution to meet the exclusive customization needs of different customers. Zhonghai Mitsubishi adheres to the core science and technology strategy, continuously improves the core technology and R & D technology of the product, and has the A -level qualification of elevator manufacturing, installation, transformation and maintenance issued by the State Administration of Quality Supervision, Inspection and Quarantine.

Zhonghai Sanling Quality Assurance

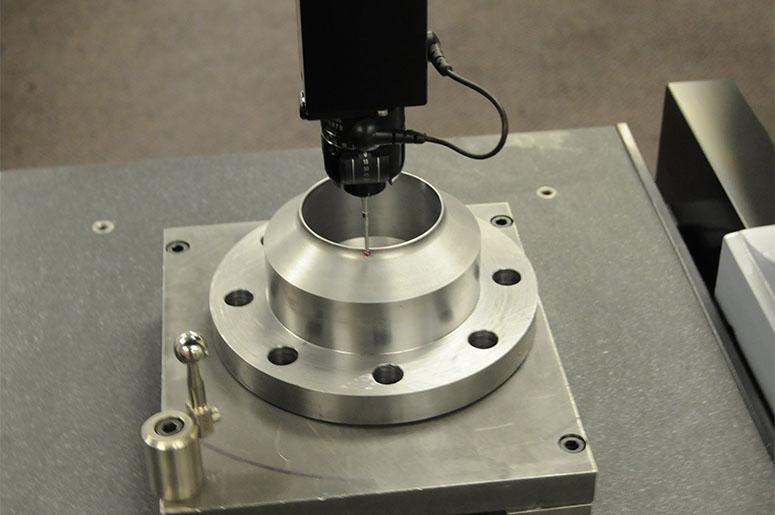

Quality is a lifeline for enterprise development. Zhonghai Mitsubishi focuses on quality guarantee, and establishes a high -precision professional elite team, imported CNC laser cutting machines, imported CNC machining centers, CNC bending machines, CNC shear machines and other international leading equipment. With advanced production and processing technology, realize the technical upgrade of the product, improve the quality of the whole machine, strengthen quality control, and customize the noble and high -end elevator products.

Zhonghai Sanling Steady innovation

Survive with professionalism, develop with innovation, and seek the future with excellence. Zhonghai Mitsubishi continues to surpass itself on the basis of inheriting the classic theory and technology of the elevator industry, creating a new standard quality management mechanism of the industry to ensure that elevators produced by Mitsubishi produced by each Taitu can exceed customer expectations. With senior technical background, professional management team, innovative technical system, and high -quality service commitment, Zhonghai Mitsubishi's product sales network not only quickly covers all parts of the country, but also exports to countries and regions such as Russia, the Middle East, Southeast Asia, South Korea, Africa and other countries and regions. The recognition and favor of many customers.

Zhonghai Sanling Win -win

Inheritance and innovation are eternal operating philosophy. As an elevator expert, Zhonghai Mitsubishi seamlessly connects the information technology of the era of big data, adheres to the modern core technology, accurate brand positioning and standardized management specifications. Operator.

In the future, Zhonghai Mitsubishi will adhere to its original intention, continuously cater to the development trend of the times, and develop a new round of elevator technology industry relay competition. Stay the sense of social responsibility while creating corporate value! Let us work together and seek common development. "Get up your sleeves and cheer!"Residential Panoramic Elevator for sale

website:

http://www.zhsl-elevator.com/Company Profile

Zhonghai SAN LING Elevator (Suzhou) Co., Ltd. is located in the most developed Yangtze River Delta region of China's economy. It is located in Suzhou, Jiangsu, a beautiful and rich Jiangnan city. It is a modern professional elevator company that integrates the R & D, design, manufacturing, sales, installation and maintenance of ladder.

The company has a modern plant with an area of more than 40,000 square meters and an office area of more than 20,000 square meters. It has a 68 -meter -high elevator test tower, and various high -precision production and testing are introduced from the United States, Japan, Belgium and other countries. Equipment, realize large -scale and beneficial precision production models, with an annual production capacity of more than 5,000 units.

Since its establishment, Zhonghai Mitsubishi Elevator has adhered to technology as the fulcrum, market -oriented, and continuously developing various energy -saving and environmentally friendly quality elevator products, and is committed to providing customers with a safer and more comfortable one -stop elevator solution. The company's product system covers passengers, cargo, sightseeing, escalators and automatic humanity. The ladder is perfect and complete. The company has a national special equipment manufacturing A -level license qualification and installation and reconstruction A -level license qualification. It has passed the ISO9001 quality management system certification, ISO14001 environmental management system certification, and OHSAS18000 occupational health and safety management system certification. It is also certified by the CE of the German TUV demonstration agency. It is an A -level enterprise recognized by the State Administration for Industry and Commerce and a prestigious enterprise in Jiangsu Province.

Based on the latest domestic and international standards, the company has formulated a strict quality management system. All factory products have passed rigorous inspection. The quality is excellent and excellent. In addition, the company has established its own new product development institution, and has a leading position in the industry in the high -speed elevator field and energy conservation and environmental protection. With continuous innovation technology, first -class talent team, and perfect after -sales service standards, the company has won a good reputation in domestic and international, developing a broad market, and its products are exported to many countries and regions at home and abroad.

Zhonghai san ling Elevator has meticulous work and eternal integrity. In the next five years, Zhonghai Mitsubishi Elevator will always be committed to creating a well -known international brand enterprise with globalization, and continue to insist on integrating integrity, responsibility, dedication, and cooperation as the core values of the company's long -term development. Enterprise spirit, adhere to the business philosophy of integrity operations, continuous progress, and win -win cooperation, and run the corporate service concept of customer first and excellent services to every aspect of China Shippeed Mitsubishi production, sales and after -sales service, and provide customers with green, environmental protection, no no Worry -type integrated vertical traffic solutions provide infinitely upward personalized carrier experience for various buildings.

Avenue, Ling Yun straight up

1977

Japan Mitsubishi Electric Corporation developed a gear-free catering elevator controlled by Lored, controlled by Lored.

1983

Mitsubishi Electric Company developed the world's first transformer transformer -driven elevator.

1985

Mitsubishi Motor Company developed a spiral escalator operating curve and successfully put into production. Spiral escalator can save architectural space and have decorative art effects.

1990

Mitsubishi Electric Company used the variable frequency drive system for hydraulic elevator for the first time.

1991

Mitsubishi Electric Corporation developed a large upgrade height escalator with an intermediate horizontal section. This multi -sloping escalator can reduce passengers' fear of height when a large increase in height, and can coordinate configuration with the building structure of the building.

1993

Mitsubishi Electric installed a 12.50m/S -speed ultra -high -speed passenger elevator at the LANDMARK Building in Yokohama, Japan. It was the fastest passenger elevator at that time at that time. Ultra -high -speed elevators are often used in TV towers, ultra -high buildings and other significant buildings.

1996

Mitsubishi Motor Company developed a double -layer high -speed elevator with a permanent magnet motor without gear traction machine and a dual -disc braking system, which was installed in the MORI building in Shanghai.

From April 17th to 20th, 2002, Mitsubishi Motor Corporation exhibited an automatic escalator model for high -speed operation at the 5th China International Elevator Exhibition. Pangic telescopic driving rack structures can change the interval between the steps during runtime, thereby changing the speed. The speed of its tilt section is 1.5 times that of the speed of the entrance and exit level, which not only shortens the passenger's ladder time, but also improves the safety and stability of the escalator on the escalator.

Zhonghai SAN LING Elevator (Suzhou) Co., Ltd.锛圱he registered capital is 108 million yuan锛夛紝It is a modern elevator company that was co -founded by the national high -tech enterprise Suzhou Sueling Elevator Co., Ltd. and Macau Zhonghai Mitsubishi Elevator Investment Co., Ltd. and the introduction of scientific and technological achievements jointly founded锛孴he design, development, manufacturing, sales, installation, and maintenance of modern professional elevator companies established on January 3, 2017. The product covers a variety of elevator categories, including passenger elevators, sightseeing elevators, medical elevators, debris elevators, escalators, and automatic sidewalk products. It has the A -level qualification of elevator manufacturing, installation, transformation and maintenance issued by the State Administration of Quality Supervision and Inspection Essence.

Zhonghai sanling Elevator adheres to the corporate spirit of "honoring sincerity, Yu Gathering in Germany, high -efficiency, and innovative quality", and has built a modern elevator manufacturing base that integrates design, development, manufacturing, sales, installation, and maintenance. The perfect after -sales service network provides reliable vertical transportation for the upward development of global cities.

Zhonghai Sanling category diverse

As a domestic professional elevator manufacturing enterprise, China Shipping Mitsubishi uses the high standards of Industry 4.0, exclusive research and development and production of multiple elevator series products, covering passenger elevators, sightseeing elevators, medical elevators, cargo carries, miscellaneous elevators, escalators, automatic sidewalk products Waiting for multi -category elevators can provide a comprehensive security transformation solution to meet the exclusive customization needs of different customers. Zhonghai Mitsubishi adheres to the core science and technology strategy, continuously improves the core technology and R & D technology of the product, and has the A -level qualification of elevator manufacturing, installation, transformation and maintenance issued by the State Administration of Quality Supervision, Inspection and Quarantine.

Zhonghai Sanling Quality Assurance

Quality is a lifeline for enterprise development. Zhonghai Mitsubishi focuses on quality guarantee, and establishes a high -precision professional elite team, imported CNC laser cutting machines, imported CNC machining centers, CNC bending machines, CNC shear machines and other international leading equipment. With advanced production and processing technology, realize the technical upgrade of the product, improve the quality of the whole machine, strengthen quality control, and customize the noble and high -end elevator products.

Zhonghai Sanling Steady innovation

Survive with professionalism, develop with innovation, and seek the future with excellence. Zhonghai Mitsubishi continues to surpass itself on the basis of inheriting the classic theory and technology of the elevator industry, creating a new standard quality management mechanism of the industry to ensure that elevators produced by Mitsubishi produced by each Taitu can exceed customer expectations. With senior technical background, professional management team, innovative technical system, and high -quality service commitment, Zhonghai Mitsubishi's product sales network not only quickly covers all parts of the country, but also exports to countries and regions such as Russia, the Middle East, Southeast Asia, South Korea, Africa and other countries and regions. The recognition and favor of many customers.

Zhonghai Sanling Win -win

Inheritance and innovation are eternal operating philosophy. As an elevator expert, Zhonghai Mitsubishi seamlessly connects the information technology of the era of big data, adheres to the modern core technology, accurate brand positioning and standardized management specifications. Operator.

In the future, Zhonghai Mitsubishi will adhere to its original intention, continuously cater to the development trend of the times, and develop a new round of elevator technology industry relay competition. Stay the sense of social responsibility while creating corporate value! Let us work together and seek common development. "Get up your sleeves and cheer!"Residential Panoramic Elevator for sale

website:http://www.zhsl-elevator.com/