How to Ensure Safety of Portable Concrete Pump When Pouring for Small Water Facilities

When contractors look for efficient and flexible equipment to handle construction tasks in small-scale water facility projects, a portable concrete pump often becomes the first choice. Its compact structure, mobility, and ability to deliver concrete precisely where needed make it an ideal machine for tight work environments such as small dams, rural water storage tanks, irrigation channels, or mini wastewater treatment plants. With increasing demand, many buyers explore mini concrete pumps for sale to save costs and increase project efficiency. However, when working in environments involving water or high humidity, safety becomes a top priority. Portable pumps must not only deliver concrete effectively but also operate without endangering workers, equipment, or the facility itself. Ensuring safety requires a combination of proper planning, equipment checks, site management, and operator training.

Understanding the Risks in Small Water Facility Projects

Before any concrete pouring begins, it is important to identify the unique risks associated with small water facility construction. Unlike urban building projects, these sites often have uneven ground, limited vehicle access, and proximity to water, which increases the potential for slips, equipment instability, and electrical hazards. A portable concrete pump(https://aimixgroup.com/concrete-pump/portable-concrete-pump/) in such settings must operate on stable ground to avoid tipping. Additionally, since small-scale facilities are often located in rural or less-developed areas, emergency services may not be readily available, making accident prevention even more crucial. Buyers considering mini concrete pumps for sale should be aware that not all pumps are equally suitable for wet or uneven sites, and the wrong choice could compromise safety.

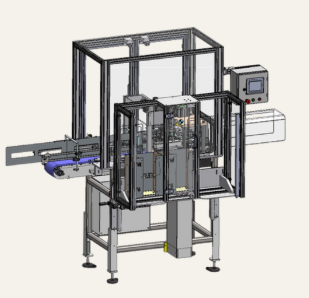

Selecting the Right Equipment for Safe Operation

Choosing the right equipment is the first step in ensuring safe concrete pouring. A portable concrete pump must have a stable base, sufficient ground clearance, and an appropriate pumping capacity for the project’s scale. Overloading the pump can lead to mechanical failure or instability, especially in soft or waterlogged soil conditions. For small water facility work, it is wise to select models with robust outriggers, non-slip platforms, and corrosion-resistant materials. Many suppliers offer mini concrete pumps for sale(https://aimixgroup.com/concrete-pump/mini-type/) that are specifically designed for harsh environments, featuring sealed electrical systems and stainless-steel components to prevent water damage. Proper selection helps minimize operational hazards and equipment breakdowns.

Pre-Operation Inspection and Maintenance

Before starting any pouring work, a thorough inspection of the portable concrete pump is essential. This includes checking hydraulic systems, ensuring all safety guards are in place, inspecting the boom (if applicable) for cracks or wear, and verifying that all control systems function properly. In small water facility projects, particular attention should be given to waterproofing seals and hose connections, as leaks can cause both equipment damage and safety risks. Operators should also confirm that emergency shut-off systems are operational. Regular preventive maintenance—especially cleaning and lubricating moving parts—keeps the pump in safe working condition. Contractors who purchase mini concrete pumps for sale should follow the manufacturer’s recommended service intervals and keep detailed maintenance logs to comply with safety standards.

Safe Positioning and Setup of the Pump

Setting up a portable concrete pump in a small water facility site requires careful positioning. The pump should be placed on stable, level ground that can support its weight and vibration during operation. Outriggers must be fully extended and secured, with base plates or mats used if the ground is soft. In areas close to water, a safe distance should be maintained to prevent accidental slips or flooding of the equipment. Site supervisors should designate clear working zones, ensuring that only trained personnel are allowed within the pump’s operating area. For those using newly acquired mini concrete pumps for sale, this setup process should be practiced during training sessions to familiarize the crew with safe procedures.

Hose Handling and Pouring Technique

When operating a portable concrete pump, improper hose handling is one of the most common causes of injury. The discharge hose can move violently due to concrete pressure changes, especially when starting or stopping the pump. Workers should always maintain a firm grip on the hose and stand in a balanced position. Communication between the hose handler and the pump operator is crucial to avoid sudden surges or blockages. In water facility projects, where surfaces may be slippery, additional anti-slip footwear and hose supports should be used. Buyers who invest in mini concrete pumps for sale should ensure the equipment includes safety features like pressure relief valves and flexible hose supports to reduce operational hazards.

Electrical and Water Safety Precautions

Operating in or near water brings specific safety challenges. A portable concrete pump should have all electrical systems properly insulated and protected from moisture. Extension cords and electrical connections must be kept away from water sources, and ground fault circuit interrupters (GFCIs) should be used whenever possible. Pumps designed for wet environments often come with waterproof enclosures and elevated control panels. In addition, operators must be trained to shut down the pump immediately in case of water ingress or electrical fault. When evaluating mini concrete pumps for sale, buyers should check whether the model complies with relevant waterproofing and electrical safety standards.

Training and Crew Communication

Even the best equipment cannot guarantee safety without properly trained operators. Workers must understand the correct procedures for setting up, operating, and shutting down the portable concrete pump, as well as how to handle emergencies. Training should include safe hose handling techniques, recognizing signs of equipment malfunction, and knowing how to respond to pump blockages. Crew members must also be trained in basic first aid, especially when working in remote small water facility sites. For companies acquiring mini concrete pumps for sale, it is recommended to request training sessions from the supplier or manufacturer to ensure all safety protocols are followed.

Continuous Monitoring During Pouring

Safety does not end once pouring starts. Operators and supervisors should continuously monitor the portable concrete pump for unusual noises, vibrations, or changes in pumping pressure. Any sign of malfunction should prompt an immediate shutdown and inspection. In small water facility projects, constant vigilance is necessary due to the risk of environmental changes—such as sudden water level rises—that could affect stability. Using mini concrete pumps for sale with built-in sensors and remote monitoring systems can enhance safety by providing real-time alerts on equipment status.

Conclusion

A portable concrete pump is an indispensable tool for small water facility projects, offering precision and efficiency in concrete delivery even in tight or challenging locations. However, safety must always be the top priority when operating such equipment near water or in wet conditions. From selecting the right pump model and performing thorough pre-operation checks to ensuring proper setup, hose handling, electrical safety, and continuous monitoring, every step plays a role in preventing accidents. Investing in high-quality mini concrete pumps for sale with appropriate safety features not only improves job site security but also extends equipment lifespan and ensures consistent performance. With careful planning, trained crews, and the right machinery, pouring concrete for small water facilities can be both safe and highly productive.

When contractors look for efficient and flexible equipment to handle construction tasks in small-scale water facility projects, a portable concrete pump often becomes the first choice. Its compact structure, mobility, and ability to deliver concrete precisely where needed make it an ideal machine for tight work environments such as small dams, rural water storage tanks, irrigation channels, or mini wastewater treatment plants. With increasing demand, many buyers explore mini concrete pumps for sale to save costs and increase project efficiency. However, when working in environments involving water or high humidity, safety becomes a top priority. Portable pumps must not only deliver concrete effectively but also operate without endangering workers, equipment, or the facility itself. Ensuring safety requires a combination of proper planning, equipment checks, site management, and operator training.

Understanding the Risks in Small Water Facility Projects

Before any concrete pouring begins, it is important to identify the unique risks associated with small water facility construction. Unlike urban building projects, these sites often have uneven ground, limited vehicle access, and proximity to water, which increases the potential for slips, equipment instability, and electrical hazards. A portable concrete pump(https://aimixgroup.com/concrete-pump/portable-concrete-pump/) in such settings must operate on stable ground to avoid tipping. Additionally, since small-scale facilities are often located in rural or less-developed areas, emergency services may not be readily available, making accident prevention even more crucial. Buyers considering mini concrete pumps for sale should be aware that not all pumps are equally suitable for wet or uneven sites, and the wrong choice could compromise safety.

Selecting the Right Equipment for Safe Operation

Choosing the right equipment is the first step in ensuring safe concrete pouring. A portable concrete pump must have a stable base, sufficient ground clearance, and an appropriate pumping capacity for the project’s scale. Overloading the pump can lead to mechanical failure or instability, especially in soft or waterlogged soil conditions. For small water facility work, it is wise to select models with robust outriggers, non-slip platforms, and corrosion-resistant materials. Many suppliers offer mini concrete pumps for sale(https://aimixgroup.com/concrete-pump/mini-type/) that are specifically designed for harsh environments, featuring sealed electrical systems and stainless-steel components to prevent water damage. Proper selection helps minimize operational hazards and equipment breakdowns.

Pre-Operation Inspection and Maintenance

Before starting any pouring work, a thorough inspection of the portable concrete pump is essential. This includes checking hydraulic systems, ensuring all safety guards are in place, inspecting the boom (if applicable) for cracks or wear, and verifying that all control systems function properly. In small water facility projects, particular attention should be given to waterproofing seals and hose connections, as leaks can cause both equipment damage and safety risks. Operators should also confirm that emergency shut-off systems are operational. Regular preventive maintenance—especially cleaning and lubricating moving parts—keeps the pump in safe working condition. Contractors who purchase mini concrete pumps for sale should follow the manufacturer’s recommended service intervals and keep detailed maintenance logs to comply with safety standards.

Safe Positioning and Setup of the Pump

Setting up a portable concrete pump in a small water facility site requires careful positioning. The pump should be placed on stable, level ground that can support its weight and vibration during operation. Outriggers must be fully extended and secured, with base plates or mats used if the ground is soft. In areas close to water, a safe distance should be maintained to prevent accidental slips or flooding of the equipment. Site supervisors should designate clear working zones, ensuring that only trained personnel are allowed within the pump’s operating area. For those using newly acquired mini concrete pumps for sale, this setup process should be practiced during training sessions to familiarize the crew with safe procedures.

Hose Handling and Pouring Technique

When operating a portable concrete pump, improper hose handling is one of the most common causes of injury. The discharge hose can move violently due to concrete pressure changes, especially when starting or stopping the pump. Workers should always maintain a firm grip on the hose and stand in a balanced position. Communication between the hose handler and the pump operator is crucial to avoid sudden surges or blockages. In water facility projects, where surfaces may be slippery, additional anti-slip footwear and hose supports should be used. Buyers who invest in mini concrete pumps for sale should ensure the equipment includes safety features like pressure relief valves and flexible hose supports to reduce operational hazards.

Electrical and Water Safety Precautions

Operating in or near water brings specific safety challenges. A portable concrete pump should have all electrical systems properly insulated and protected from moisture. Extension cords and electrical connections must be kept away from water sources, and ground fault circuit interrupters (GFCIs) should be used whenever possible. Pumps designed for wet environments often come with waterproof enclosures and elevated control panels. In addition, operators must be trained to shut down the pump immediately in case of water ingress or electrical fault. When evaluating mini concrete pumps for sale, buyers should check whether the model complies with relevant waterproofing and electrical safety standards.

Training and Crew Communication

Even the best equipment cannot guarantee safety without properly trained operators. Workers must understand the correct procedures for setting up, operating, and shutting down the portable concrete pump, as well as how to handle emergencies. Training should include safe hose handling techniques, recognizing signs of equipment malfunction, and knowing how to respond to pump blockages. Crew members must also be trained in basic first aid, especially when working in remote small water facility sites. For companies acquiring mini concrete pumps for sale, it is recommended to request training sessions from the supplier or manufacturer to ensure all safety protocols are followed.

Continuous Monitoring During Pouring

Safety does not end once pouring starts. Operators and supervisors should continuously monitor the portable concrete pump for unusual noises, vibrations, or changes in pumping pressure. Any sign of malfunction should prompt an immediate shutdown and inspection. In small water facility projects, constant vigilance is necessary due to the risk of environmental changes—such as sudden water level rises—that could affect stability. Using mini concrete pumps for sale with built-in sensors and remote monitoring systems can enhance safety by providing real-time alerts on equipment status.

Conclusion

A portable concrete pump is an indispensable tool for small water facility projects, offering precision and efficiency in concrete delivery even in tight or challenging locations. However, safety must always be the top priority when operating such equipment near water or in wet conditions. From selecting the right pump model and performing thorough pre-operation checks to ensuring proper setup, hose handling, electrical safety, and continuous monitoring, every step plays a role in preventing accidents. Investing in high-quality mini concrete pumps for sale with appropriate safety features not only improves job site security but also extends equipment lifespan and ensures consistent performance. With careful planning, trained crews, and the right machinery, pouring concrete for small water facilities can be both safe and highly productive.

How to Ensure Safety of Portable Concrete Pump When Pouring for Small Water Facilities

When contractors look for efficient and flexible equipment to handle construction tasks in small-scale water facility projects, a portable concrete pump often becomes the first choice. Its compact structure, mobility, and ability to deliver concrete precisely where needed make it an ideal machine for tight work environments such as small dams, rural water storage tanks, irrigation channels, or mini wastewater treatment plants. With increasing demand, many buyers explore mini concrete pumps for sale to save costs and increase project efficiency. However, when working in environments involving water or high humidity, safety becomes a top priority. Portable pumps must not only deliver concrete effectively but also operate without endangering workers, equipment, or the facility itself. Ensuring safety requires a combination of proper planning, equipment checks, site management, and operator training.

Understanding the Risks in Small Water Facility Projects

Before any concrete pouring begins, it is important to identify the unique risks associated with small water facility construction. Unlike urban building projects, these sites often have uneven ground, limited vehicle access, and proximity to water, which increases the potential for slips, equipment instability, and electrical hazards. A portable concrete pump(https://aimixgroup.com/concrete-pump/portable-concrete-pump/) in such settings must operate on stable ground to avoid tipping. Additionally, since small-scale facilities are often located in rural or less-developed areas, emergency services may not be readily available, making accident prevention even more crucial. Buyers considering mini concrete pumps for sale should be aware that not all pumps are equally suitable for wet or uneven sites, and the wrong choice could compromise safety.

Selecting the Right Equipment for Safe Operation

Choosing the right equipment is the first step in ensuring safe concrete pouring. A portable concrete pump must have a stable base, sufficient ground clearance, and an appropriate pumping capacity for the project’s scale. Overloading the pump can lead to mechanical failure or instability, especially in soft or waterlogged soil conditions. For small water facility work, it is wise to select models with robust outriggers, non-slip platforms, and corrosion-resistant materials. Many suppliers offer mini concrete pumps for sale(https://aimixgroup.com/concrete-pump/mini-type/) that are specifically designed for harsh environments, featuring sealed electrical systems and stainless-steel components to prevent water damage. Proper selection helps minimize operational hazards and equipment breakdowns.

Pre-Operation Inspection and Maintenance

Before starting any pouring work, a thorough inspection of the portable concrete pump is essential. This includes checking hydraulic systems, ensuring all safety guards are in place, inspecting the boom (if applicable) for cracks or wear, and verifying that all control systems function properly. In small water facility projects, particular attention should be given to waterproofing seals and hose connections, as leaks can cause both equipment damage and safety risks. Operators should also confirm that emergency shut-off systems are operational. Regular preventive maintenance—especially cleaning and lubricating moving parts—keeps the pump in safe working condition. Contractors who purchase mini concrete pumps for sale should follow the manufacturer’s recommended service intervals and keep detailed maintenance logs to comply with safety standards.

Safe Positioning and Setup of the Pump

Setting up a portable concrete pump in a small water facility site requires careful positioning. The pump should be placed on stable, level ground that can support its weight and vibration during operation. Outriggers must be fully extended and secured, with base plates or mats used if the ground is soft. In areas close to water, a safe distance should be maintained to prevent accidental slips or flooding of the equipment. Site supervisors should designate clear working zones, ensuring that only trained personnel are allowed within the pump’s operating area. For those using newly acquired mini concrete pumps for sale, this setup process should be practiced during training sessions to familiarize the crew with safe procedures.

Hose Handling and Pouring Technique

When operating a portable concrete pump, improper hose handling is one of the most common causes of injury. The discharge hose can move violently due to concrete pressure changes, especially when starting or stopping the pump. Workers should always maintain a firm grip on the hose and stand in a balanced position. Communication between the hose handler and the pump operator is crucial to avoid sudden surges or blockages. In water facility projects, where surfaces may be slippery, additional anti-slip footwear and hose supports should be used. Buyers who invest in mini concrete pumps for sale should ensure the equipment includes safety features like pressure relief valves and flexible hose supports to reduce operational hazards.

Electrical and Water Safety Precautions

Operating in or near water brings specific safety challenges. A portable concrete pump should have all electrical systems properly insulated and protected from moisture. Extension cords and electrical connections must be kept away from water sources, and ground fault circuit interrupters (GFCIs) should be used whenever possible. Pumps designed for wet environments often come with waterproof enclosures and elevated control panels. In addition, operators must be trained to shut down the pump immediately in case of water ingress or electrical fault. When evaluating mini concrete pumps for sale, buyers should check whether the model complies with relevant waterproofing and electrical safety standards.

Training and Crew Communication

Even the best equipment cannot guarantee safety without properly trained operators. Workers must understand the correct procedures for setting up, operating, and shutting down the portable concrete pump, as well as how to handle emergencies. Training should include safe hose handling techniques, recognizing signs of equipment malfunction, and knowing how to respond to pump blockages. Crew members must also be trained in basic first aid, especially when working in remote small water facility sites. For companies acquiring mini concrete pumps for sale, it is recommended to request training sessions from the supplier or manufacturer to ensure all safety protocols are followed.

Continuous Monitoring During Pouring

Safety does not end once pouring starts. Operators and supervisors should continuously monitor the portable concrete pump for unusual noises, vibrations, or changes in pumping pressure. Any sign of malfunction should prompt an immediate shutdown and inspection. In small water facility projects, constant vigilance is necessary due to the risk of environmental changes—such as sudden water level rises—that could affect stability. Using mini concrete pumps for sale with built-in sensors and remote monitoring systems can enhance safety by providing real-time alerts on equipment status.

Conclusion

A portable concrete pump is an indispensable tool for small water facility projects, offering precision and efficiency in concrete delivery even in tight or challenging locations. However, safety must always be the top priority when operating such equipment near water or in wet conditions. From selecting the right pump model and performing thorough pre-operation checks to ensuring proper setup, hose handling, electrical safety, and continuous monitoring, every step plays a role in preventing accidents. Investing in high-quality mini concrete pumps for sale with appropriate safety features not only improves job site security but also extends equipment lifespan and ensures consistent performance. With careful planning, trained crews, and the right machinery, pouring concrete for small water facilities can be both safe and highly productive.

0 Comentários

0 Compartilhamentos

0 Anterior