Key Advantages of Aluminium Die Casting Over Other Methods

Introduction

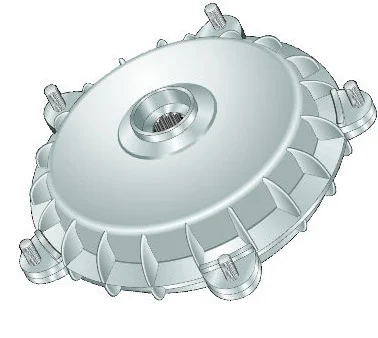

At Auto Die Cast, we have spent years working closely with industries that need strong, lightweight, and detailed metal parts. One method that stands out is Aluminium Die Casting. This process helps create high-quality metal parts quickly and cost-effectively.

Many Aluminium Die Casting Manufacturers choose this method because it allows for faster production, better accuracy, and strong parts that are still light in weight. From car parts to electronic devices, aluminium die casting is used in many different fields.

we will explain how aluminium die casting works and why it is better than other methods like sand casting or zinc casting. Whether you’re looking for durability, speed, or cost savings, aluminium die casting offers many benefits you should know about.

What Is Aluminium Die Casting and How Does It Work?

Aluminium die casting is a process where melted aluminium is forced into a steel mold (also called a die) at high pressure. Once the aluminium cools down and hardens, it takes the shape of the mold and becomes a strong, detailed part.

This method is widely used by Aluminium Die Casting Manufacturers because:

-

It’s fast

-

It can create parts with very fine details

-

It doesn’t need a lot of finishing or polishing

There are other methods like gravity castings, where metal is poured into a mold without pressure. But die casting uses pressure, which gives much better results for mass production.

Many Die Casting Manufacturers prefer this method because it helps them produce thousands of parts in a short amount of time.

Why Is Aluminium Die Casting Preferred Over Other Casting Methods?

There are many ways to make metal parts, but aluminium die casting has clear advantages over others like:

-

Sand Casting: Slower, less accurate, and requires more finishing

-

Investment Casting: Good for small parts, but costly and time-consuming

-

Zamak Die Casting or Zinc Die Casting: Not as lightweight or corrosion-resistant as aluminium

Aluminium Die Casting is preferred because:

-

It creates parts faster

-

It produces less waste

-

It gives a smoother finish

-

It is good for making complex shapes

-

It works well with automation

Top Aluminium Die Casting Manufacturers rely on this method because it balances speed, quality, and cost. Over the years at Auto Die Cast, we’ve seen how our clients prefer aluminium die casting because of its consistent and reliable results.

What Are the Strength and Weight Benefits of Aluminium Die Casting?

One of the biggest reasons companies choose aluminium die casting is the material’s strength-to-weight ratio. Aluminium is strong enough to handle heavy use, yet light enough to reduce overall product weight.

Main benefits include:

-

Lightweight parts: Great for cars, airplanes, and machines

-

Strong performance: Can handle stress and wear

-

Better energy use: Lighter parts improve fuel efficiency

Compared to other metals like zinc or steel, aluminium offers a better mix of lightness and durability. That’s why Aluminium Die Casting Manufacturers often get requests from the automotive, aerospace, and electronics industries.

At Auto Die Cast, we’ve helped our clients reduce product weight without losing strength or quality—just by switching to aluminium die casting.

How Accurate Is Aluminium Die Casting Compared to Other Methods?

When making metal parts, precision matters. Aluminium die casting offers great accuracy, even for complex designs.

Accuracy advantages:

-

Tight tolerances: Parts come out the right size, every time

-

Smooth surfaces: No need for extra polishing

-

Thin walls and sharp details: Without compromising strength

Other methods like sand casting or gravity castings often need extra work to finish the part. But aluminium die casting makes it possible to get near-final parts directly from the mold.

That’s why so many Die Casting Manufacturers trust this process for projects that require exact measurements and clean finishes. At Auto Die Cast, we’ve used this process to meet even the strictest client specifications.

Is Aluminium Die Casting Suitable for High-Volume Production?

Yes, aluminium die casting is one of the best methods for making large numbers of parts quickly. It’s a favorite for mass production.

Why it works well for big orders:

-

Fast cycle time: Makes thousands of parts in a short time

-

Reusable molds: One mold can be used again and again

-

Works with machines: Can be automated to save time and labor

Most Aluminium Die Casting Manufacturers rely on this method when they need speed and quality at the same time. It’s a smart choice for companies that want to produce parts without long delays or high labor costs.

We’ve helped clients fulfill big orders at Auto Die Cast without compromising on detail or accuracy, thanks to this highly efficient process.

What Are the Most Common Applications of Aluminium Die Casting?

Aluminium Die Casting is used in many industries. It’s useful because it can create strong, light, and precise parts in large numbers.

Common uses include:

-

Automotive: Engine covers, gear parts, brackets, housings

-

Electronics: Heat sinks, LED frames, enclosures

-

Aerospace: Lightweight structural parts

-

Home appliances: Handles, motor covers, machine frames

-

Telecom and networking: Connectors, casings, signal housings

Because aluminium resists rust and wear, it’s ideal for both indoor and outdoor use. Many of the top Aluminium Die Casting Manufacturers supply these parts to leading global brands.

At Auto Die Cast, we’ve worked with companies from all these sectors, offering dependable and long-lasting aluminium cast parts that perform well in real-world conditions.

Conclusion

For companies that want fast, accurate, and cost-effective parts, Aluminium Die Casting is a smart choice. It beats other casting methods in terms of speed, strength, and detail. Whether you're building cars, gadgets, or machines, aluminium die casting can help you improve your products while keeping costs low.

With over two decades of experience, Auto Die Cast stands as one of the trusted Aluminium Die Casting Manufacturers, offering top-quality parts that meet global standards. Our clients rely on us for consistent results, competitive pricing, and expert support.

Looking for strong and lightweight aluminium die cast parts? Contact Auto Die Cast today to get started.

- Information Technology

- Office Equipment and Supplies

- Cars and Trucks

- Persons

- Books and Authors

- Tutorials

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Jocuri

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Alte

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness