Precision in Flight: The Rise of Aerospace Machine Tools

The aerospace industry relies on unmatched precision and performance, and machine tools play a central role in fabricating complex components. Aerospace machine tools enable the production of airframes, engines, landing gear, and other critical parts using high-strength materials like titanium and carbon composites. As air travel grows and defense budgets rise, the demand for high-performance machine tools is soaring.

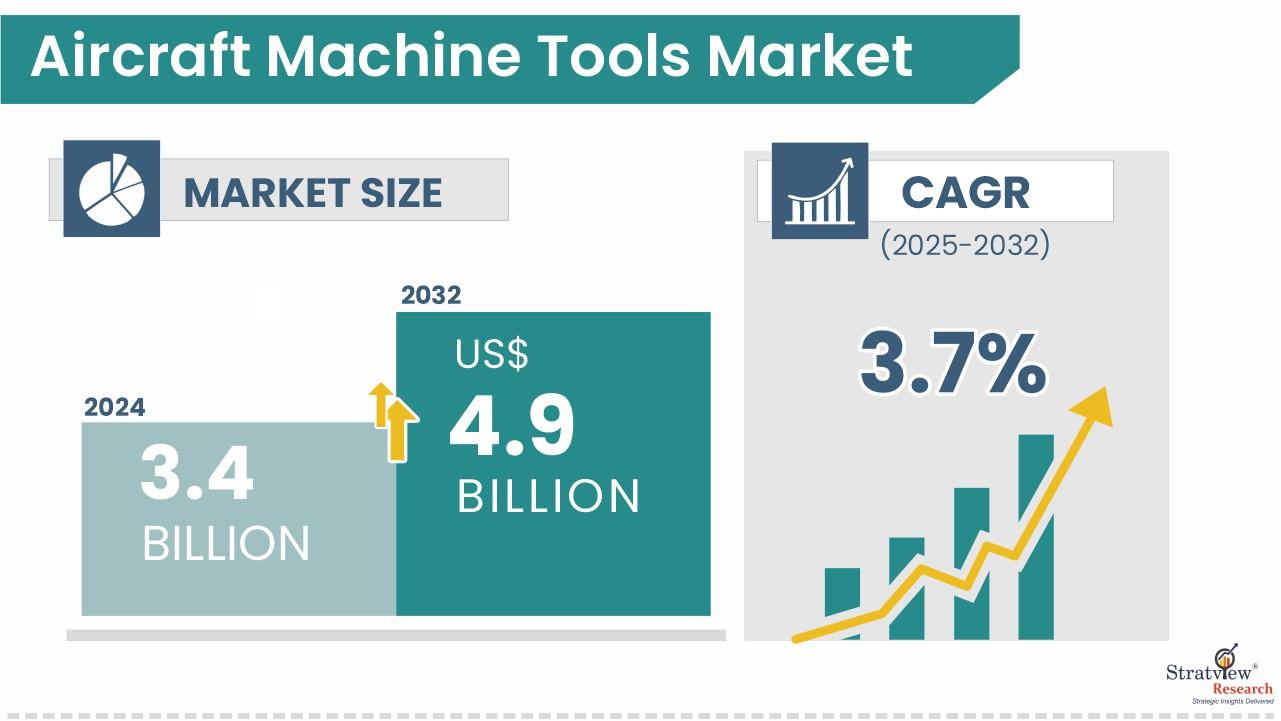

According to Stratview Research, the aircraft machine tools market size was USD 3.4 billion in 2024 and is likely to grow at a CAGR of 3.7% during 2025-2032 to reach USD 4.9 billion in 2032.

Download the sample report here, to uncover in-depth insights.

https://stratviewresearch.com/Request-Sample/3584/aerospace-machine-tools-market.html#form

Drivers

- Commercial Aviation Growth: Increased aircraft production to meet global passenger demand is fueling machine tool usage.

- Defense Modernization Programs: Rising military investments require precision manufacturing of fighter jets, UAVs, and missile systems.

- Adoption of Lightweight Materials: Machining titanium, aluminum, and composites demands advanced tools with high-speed capabilities.

- Aftermarket and MRO Services: Rising fleet sizes are boosting demand for machining tools used in part repair and replacement.

Challenges

- High Capital Investment: Aerospace-grade CNC and multi-axis machines are expensive and require skilled operators.

- Material Machinability Issues: Tough metals and composites create wear-and-tear challenges for tools.

- Supply Chain Disruptions: Delays in semiconductor availability or tool components affect production timelines.

- Complex Quality Standards: Aerospace parts must meet rigorous quality and safety certifications.

Opportunities

- AI and Predictive Maintenance: Smart tools with sensors improve uptime and reduce unscheduled downtime.

- Emerging Markets: India, Brazil, and Southeast Asia are investing in aerospace manufacturing capabilities.

- Additive & Hybrid Machines: Combining machining and 3D printing is opening new manufacturing pathways.

- Sustainability Push: Green machining solutions with lower energy use and reduced waste are gaining popularity.

Trends

- 5-Axis and Multi-Tasking Machines: These reduce setup times and improve part accuracy.

- Tooling-as-a-Service (TaaS): Subscription-based models for tooling and software support are emerging.

- Digital Twin Adoption: Simulated machining processes are enhancing productivity and reducing trial errors.

- Customization for OEMs: Tailored machines for specific aircraft models are driving vendor differentiation.

Conclusion

The aerospace machine tools market is growing in complexity and opportunity. As manufacturers aim for tighter tolerances, faster cycles, and sustainable operations, advanced machine tools are becoming mission-critical assets.

- Information Technology

- Office Equipment and Supplies

- Cars and Trucks

- Persons

- Books and Authors

- Tutorials

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Jeux

- Gardening

- Health

- Domicile

- Literature

- Music

- Networking

- Autre

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness