Wind Turbine Composites Market Strengthened by Lower Maintenance Needs

Wind Turbine Composites Market grows with rising demand for lightweight, durable materials boosting turbine efficiency, lowering maintenance, and supporting clean energy goals.

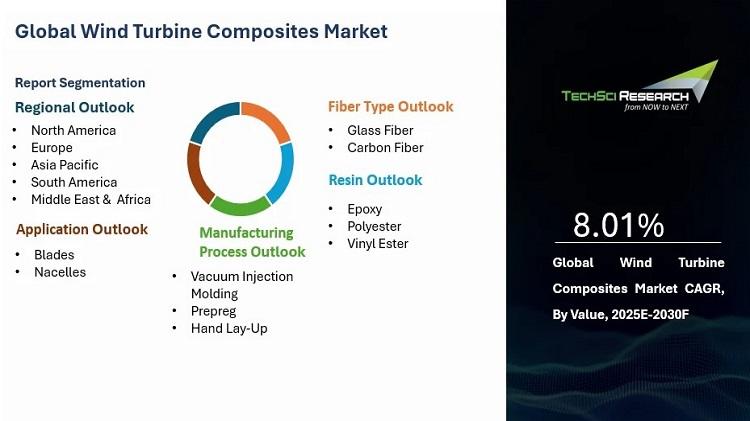

According to the TechSci Research report titled “Wind Turbine Composites Market – Global Industry Size, Share, Trends, Competition Forecast & Opportunities, 2030F”, the global wind turbine composites market was valued at USD 15.78 billion in 2024 and is projected to reach USD 25.28 billion by 2030, growing at a CAGR of 8.01% during the forecast period. This market is witnessing robust expansion, primarily driven by the accelerating shift toward renewable energy sources and increasing global focus on sustainability and carbon neutrality.

The growing awareness about climate change and the need to reduce greenhouse gas emissions have prompted governments, industries, and utilities to prioritize renewable energy investments. Wind energy, being one of the most mature and efficient renewable technologies, is at the forefront of this transition. Consequently, the demand for wind turbines—and by extension, high-performance materials used in their construction—has significantly increased. Composites play a vital role in this evolution due to their superior characteristics such as high strength-to-weight ratio, resistance to corrosion, and durability, which are essential for manufacturing long, efficient, and durable turbine blades.

Market Drivers and Industry Dynamics

One of the core drivers of the wind turbine composites market is the global push for decarbonization and clean energy. Regulatory frameworks such as the European Green Deal, the U.S. Inflation Reduction Act, and various national renewable energy targets are fostering increased investments in wind power. These investments, both onshore and offshore, demand next-generation materials that can withstand extreme environmental conditions while improving the efficiency and lifespan of wind turbines.

Composite materials, particularly glass fiber-reinforced polymers (GFRP) and carbon fiber-reinforced polymers (CFRP), are increasingly favored in turbine manufacturing due to their ability to reduce weight without compromising structural integrity. This weight reduction directly enhances turbine efficiency by allowing for longer blades and improved energy capture, even in low-wind conditions. Additionally, composites contribute to lower maintenance costs and extended equipment life, making them a cost-effective choice over the long term.

Advancements in Composite Technologies

Technological advancements in composite materials and manufacturing techniques are further fueling market growth. Innovations such as automated fiber placement (AFP), 3D printing, and the development of thermoplastic and recyclable composites are improving production efficiency, reducing waste, and lowering costs. These innovations not only make wind energy more economically viable but also address concerns around the environmental impact of decommissioned wind turbine blades, many of which are currently landfilled.

Another noteworthy development is the integration of smart materials and embedded sensors in composite components. These smart composites enable real-time structural health monitoring, allowing operators to predict and prevent failures, optimize maintenance schedules, and enhance system reliability. This capability is especially critical for offshore wind turbines, which operate in remote and harsh marine environments where maintenance is more complex and costly.

Manufacturing Process Insight

Among the various manufacturing processes used in the wind turbine composites market, the vacuum injection molding (VIM) segment held the largest market share in 2024. Also known as vacuum-assisted resin transfer molding (VARTM), this technique has gained popularity due to its ability to produce large-scale, high-performance composite parts efficiently.

In this process, dry fiber reinforcements are placed in a mold and enclosed using a vacuum bag. Resin is then infused into the fiber under vacuum pressure, ensuring complete impregnation and uniform distribution. This leads to superior mechanical properties, such as enhanced fatigue resistance and load-bearing capacity, which are essential for long-lasting wind turbine blades.

VIM is particularly suited for producing large components used in modern turbines, which increasingly feature blades over 80 meters long. Additionally, this process supports a range of resins like epoxy and vinyl ester, making it flexible across different turbine designs. Its closed-molding system also helps reduce emissions and material waste, aligning with the broader goals of sustainability in the renewable energy sector.

The scalability and environmental benefits of VIM make it an ideal solution for both onshore and offshore wind applications, especially as the industry moves toward larger and more powerful turbines. With the growth of offshore wind farms demanding durable, corrosion-resistant, and lightweight components, vacuum injection molding is poised to remain a dominant manufacturing process in this market.

Browse over XX Market data Figures spread through XX Pages and an in-depth TOC on the "Global Wind Turbine Composites Market.”

https://www.techsciresearch.com/report/wind-turbine-composites-market/29415.html

Regional Insights

Asia Pacific emerged as the fastest-growing region in the wind turbine composites market and is expected to maintain this momentum throughout the forecast period. The region’s rapid industrialization, combined with ambitious renewable energy targets, is driving demand for advanced composite materials. Countries like China, India, Japan, and Australia are investing heavily in wind energy infrastructure, both to meet growing energy demands and to address climate change.

China, the global leader in wind energy capacity, continues to expand its domestic manufacturing capabilities for both turbines and composites, making it a critical hub in the global supply chain. India is also scaling up its wind energy programs, supported by government incentives and international collaborations.

Additionally, the region benefits from cost-effective labor and raw materials, which enhance its competitiveness in manufacturing. Technological collaboration with European and North American firms further strengthens Asia Pacific’s position as a leader in composite development and deployment.

Conclusion

The global wind turbine composites market is well-positioned for continued expansion, fueled by the global decarbonization agenda, technological innovation, and the relentless growth of the wind power sector. Composites are proving to be indispensable in the quest for lighter, stronger, and more efficient wind turbine components, especially as turbine sizes and performance expectations continue to rise.

With supportive government policies, growing offshore wind investments, and sustained advancements in manufacturing technologies, the market is likely to see continued adoption and innovation. Stakeholders across the value chain—from material suppliers to turbine manufacturers—stand to benefit significantly from the evolving landscape of wind energy and the critical role of composite materials in shaping its future.

Major companies operating in the Global Wind Turbine Composites Market are:

LM Wind Power (GE Renewable Energy)

TPI Composites Inc.

Siemens Gamesa Renewable Energy

Vestas Wind Systems A/S

Suzlon Energy Limited

MFG Wind (Molded Fiber Glass Companies)

Hexcel Corporation

Toray Industries, Inc.

SGL Carbon SE

Teijin Limited

Download Free Sample Report

https://www.techsciresearch.com/sample-report.aspx?cid=29415

Customers can also request 10% free customization in this report.

“The Global Wind Turbine Composites Market is expected to rise in the upcoming years and register a significant CAGR during the forecast period. The Wind Turbine Composites Market is poised for robust growth, propelled by the accelerating global transition to renewable energy and the demand for larger, higher-performance wind turbines. The adoption of advanced composite materials offers enhanced blade strength, reduced weight, and improved durability, driving operational efficiencies and lowering maintenance expenditures. Increased capital deployment in offshore wind projects and expanding wind infrastructure globally underpin market expansion.

Furthermore, advancements in bio-based and recyclable composites present strategic opportunities for sustainable production. Supportive regulatory frameworks and government incentives aimed at carbon reduction further reinforce the market’s growth trajectory and adoption potential. Therefore, the Market of Wind Turbine Composites is expected to boost in the upcoming years.,” said Mr. Karan Chechi, Research Director of TechSci Research, a research-based management consulting firm.

“Wind Turbine Composites Market - Global Industry Size, Share, Trends, Opportunity, and Forecast, Segmented, By Fiber Type (Glass Fiber, Carbon Fiber), By Resin (Epoxy, Polyester, Vinyl Ester), By Manufacturing Process (Vacuum Injection Molding, Prepreg, Hand Lay-Up), By Application (Blades, Nacelles), By Region, By Competition, 2020-2030F”, has evaluated the future growth potential of Global Wind Turbine Composites Market and provides statistics & information on the Market size, structure, and future Market growth. The report intends to provide cutting-edge Market intelligence and help decision-makers make sound investment decisions., The report also identifies and analyzes the emerging trends along with essential drivers, challenges, and opportunities in the Global Wind Turbine Composites Market.

Contact

Techsci Research LLC

420 Lexington Avenue,

Suite 300, New York,

United States- 10170

Tel: +13322586602

Email: sales@techsciresearch.com

Website: www.techsciresearch.com

- Information Technology

- Office Equipment and Supplies

- Cars and Trucks

- Persons

- Books and Authors

- Tutorials

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Games

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness