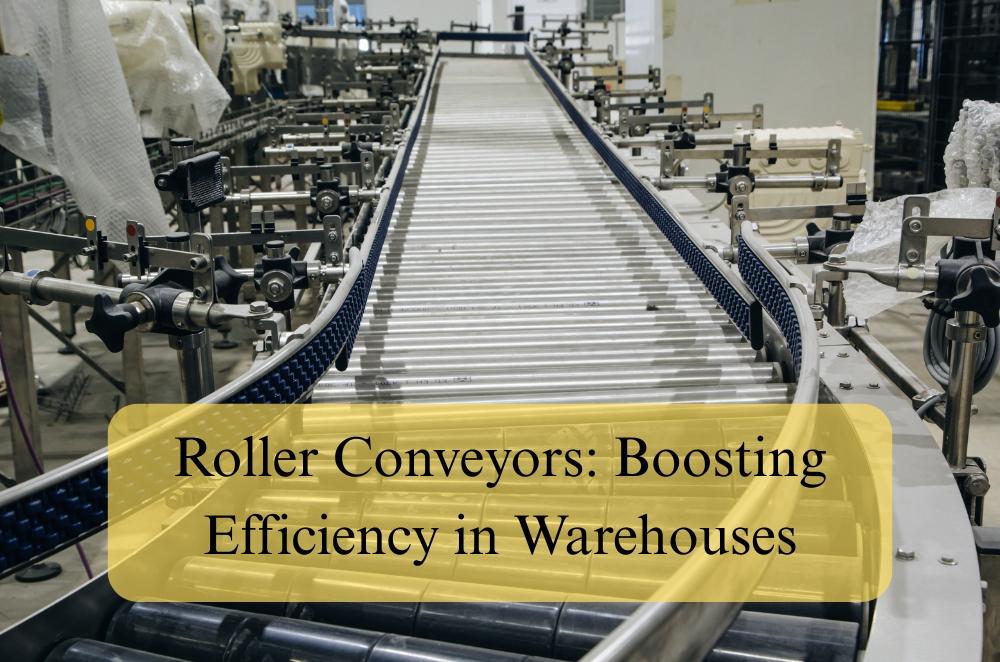

Roller Conveyors: Boosting Efficiency in Warehouses

In any warehouse, time doesn’t just feel important—it runs everything. People are under pressure to shift products fast, keep orders flowing out the door, and somehow avoid injuries while they’re at it. That’s one reason plenty of Australian businesses end up relying on roller conveyors. They’re straightforward, mostly, and they just work.

Instead of having teams lug boxes or making forklifts run laps all day, a good conveyor setup takes some of that hassle out of the way. Whether it’s boxes you’re packing, cartons waiting to be sorted, or parts lined up for assembly, smoother movement means less wasted time and fewer headaches.

But not every conveyor suits every space. The wrong choice can drag productivity down or wear out too quickly. Before you start thinking about installation, it helps to look closer at how conveyors fit into day-to-day work, and what’s worth considering first.

Why roller conveyors stand out

Plenty of smaller warehouses still rely on trolleys and hand-loading to get by. It works for a while. But when orders pile up or the team grows, those old routines can’t keep pace. Roller conveyors, whether they use gravity or a powered motor, give you a consistent, predictable flow.

A few reasons they keep showing up in busy workplaces:

-

Less manual lifting, so there’s less strain on shoulders and backs

-

Quicker movement between areas

-

Flexibility to shift layouts if you need to expand

-

A clear path through the building instead of cluttered lanes

It isn’t only about going faster. A good layout cuts down on confusion and helps everyone feel safer moving around.

Safety always matters

Even the most organised team can end up with sprains, slips or fatigue from moving items all day. It happens more than people think. Guidance about manual handling safety explains why reducing repetitive lifting matters so much.

Roller conveyors help by taking some of that load off workers. Gravity does the work, mostly. But equipment alone isn’t the fix. Training staff properly, keeping walkways clear, and setting simple routines all play a part in avoiding injuries.

Different conveyor setups

Not every roller conveyor works the same way, and picking one just because it looks solid doesn’t always end well. The choice usually comes down to what you’re moving and how quickly it needs to get from point A to B.

Some options worth weighing up:

-

Gravity conveyors: simple, affordable, easy to install. Best for lighter items that roll easily.

-

Powered rollers: better if you want a steady pace or have heavier cartons.

-

Expandable sections: handy when space changes often or needs to flex with workload.

-

Heavy-duty designs: built for large loads like pallets or bulky stock.

It comes down to the weight, speed and space you’ve got to work with.

Fitting conveyors into your routines

Adding a conveyor isn’t about cutting staff out. It’s more about letting people focus on tasks they’re better at. When you set things up right, items move smoothly from receiving to packing without everyone having to stop and carry them.

In some warehouses, conveyors link every main zone—receiving, storage, assembly and shipping. That connection reduces wasted time walking around or waiting for equipment.

It helps to ask a few practical questions first:

-

Where does work usually get stuck or pile up?

-

Are some products awkward to carry or store?

-

Would changing the height or adding guides make movement simpler?

-

Is there space to expand if demand grows?

Even small tweaks can save hours over a month.

Maintenance and staying reliable

One of the reasons roller conveyors appeal to so many operators is that they don’t need much fuss. But nothing stays trouble-free forever. Bearings wear, bolts loosen, and rollers pick up grime.

A basic upkeep routine might include:

-

Checking for cracks or dents in the frame

-

Making sure rollers spin freely without sticking

-

Cleaning off dust and debris so nothing jams

-

Tightening fittings before they become a problem

These small checks keep downtime to a minimum.

Seeing the warehouse as a whole system

Conveyors alone won’t fix every bottleneck. They’re one piece of the broader puzzle—storage racks, picking strategies, and packing benches. Looking at everything together often shows where simple changes can save time or reduce strain.

Some companies explore conveyor belts in Australia to see how automated setups fit into bigger plans. Even if you don’t need automation now, it can help to understand where the industry’s heading.

Long-term effects on people and workflow

One thing that gets missed in planning is how much easier a good setup can make the day feel. Less heavy lifting, fewer awkward corners to navigate—over time, it lifts morale. Staff stay fresher, and productivity tends to improve.

Flexibility is another part. If your product lines grow or order volumes shift, conveyors can often be rearranged without starting over. That adaptability means you’re not stuck with a layout that only fits last year’s work.

A closer look at smoother processes

You don’t have to overhaul everything at once to see gains. When roller conveyors combine with smart storage and clear processes, there’s usually an obvious difference in how fast orders move out. Examples of streamlining warehouse operations show that better flow not only improves speed. But also, it helps prevent damage, lowers error rates, and makes training new staff simpler.

The main idea isn’t to move things quicker just for the sake of it. It’s about building a system that makes sense and can handle change without constant rework.

Final thoughts

Roller conveyors might look basic, but they can reshape how a warehouse functions. When you replace a lot of manual lifting with something predictable, the day flows more easily.

With the right equipment, clear routines and a bit of planning, you’re likely to see fewer injuries and better results. It doesn’t have to be complicated. Small improvements, done steadily, usually add up to something you can measure and rely on.

- Information Technology

- Office Equipment and Supplies

- Cars and Trucks

- Persons

- Books and Authors

- Tutorials

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Games

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness