Seals Market: Ensuring Performance and Durability Across Industries

Seals are critical components used across a wide range of industrial applications to prevent the leakage of fluids and gases, control pressure, and ensure the efficient functioning of machinery. Whether in automotive engines, aerospace components, industrial machinery, or consumer products, seals play an integral role in ensuring the reliability and durability of systems. The Seals Market has seen significant growth due to the increasing demand for high-performance materials, technological advancements, and the growing need for energy efficiency and sustainability across various industries.

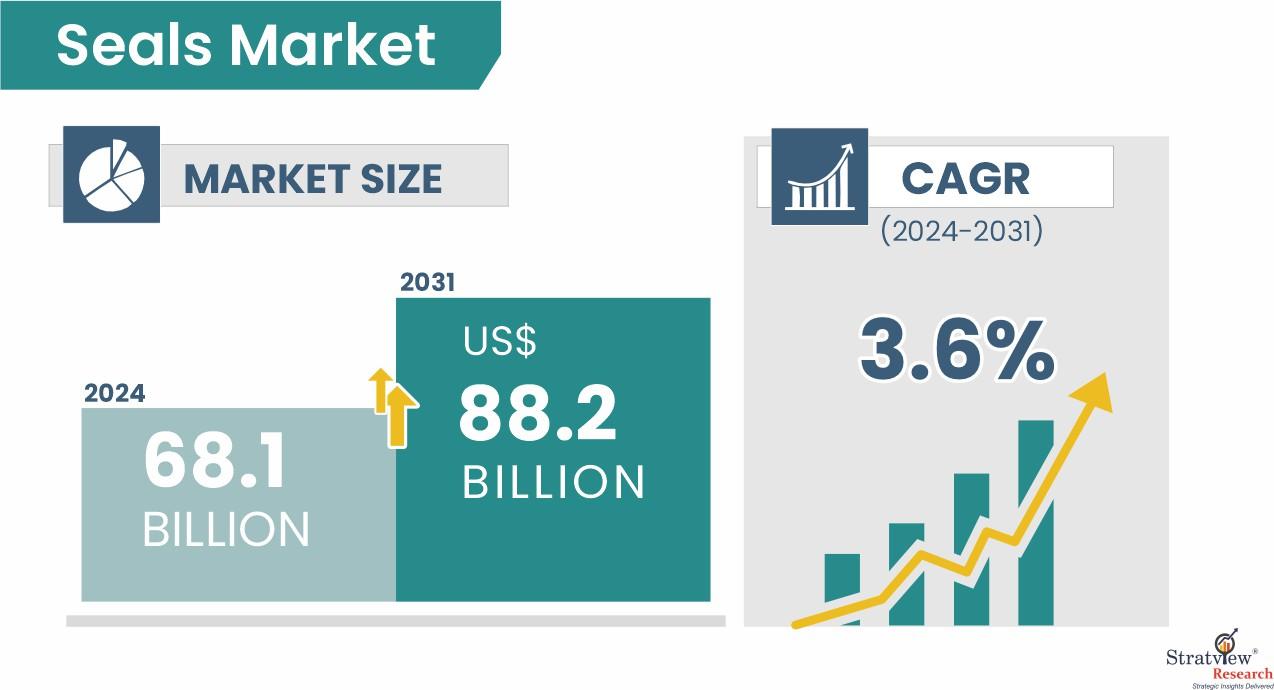

According to Stratview Research, the Seals Market is expected to grow at a CAGR of 3.6% from 2024 to 2031, reaching a market value of USD 88.2 billion by 2031. This growth is driven by the rising need for sealing solutions in sectors such as automotive, aerospace, and energy, where sealing performance is crucial for ensuring safety and operational efficiency.

Request a sample report to preview our in-depth analysis:

https://stratviewresearch.com/Request-Sample/2936/seals-market.html#form

What Are Seals?

Seals are mechanical components that close gaps between parts to prevent the leakage of fluids, gases, or debris. They are made from various materials, including rubber, metal, plastic, and composites, and are designed to perform under a range of environmental conditions such as high temperatures, pressures, and chemical exposure. The most common types of seals include O-rings, gaskets, lip seals, and rotary seals, each designed for specific applications.

Applications of Seals

- Automotive Industry: Seals are used extensively in automotive systems, including engine gaskets, brake systems, fuel systems, and air conditioning units. They ensure that the engine operates efficiently by preventing fluid leaks and ensuring optimal pressure control, which is essential for the vehicle's performance and safety.

- Aerospace and Aviation: In the aerospace industry, seals are used in aircraft engines, landing gear systems, and fuel tanks to prevent leaks and ensure the safe operation of aircraft at high altitudes and extreme temperatures. Seals in the aerospace sector need to withstand harsh environmental conditions, such as vibration, pressure fluctuations, and temperature extremes.

- Industrial Machinery and Oil & Gas: Seals are critical in industrial applications, including pumps, valves, and rotary equipment, ensuring that machinery operates smoothly and without leaks. In the oil and gas industry, seals are used in drilling operations and pipelines to prevent leakage of hazardous chemicals and gases.

Market Drivers for Seals

- Demand for High-Performance Materials: The growing need for durability, energy efficiency, and cost-effectiveness is driving the demand for high-performance seals. Advances in materials science have led to the development of seals that can withstand extreme conditions such as high temperatures, chemical exposure, and high-pressure environments.

- Growth of the Automotive and Aerospace Industries: As both industries continue to evolve, especially with the rise of electric vehicles (EVs) and the development of next-generation aircraft, the need for advanced sealing solutions is growing. High-performance seals are essential for ensuring the efficient operation and safety of these innovative systems.

- Technological Advancements in Sealing Solutions: The continuous innovation in sealing materials and manufacturing techniques is helping to enhance the performance and lifespan of seals. New materials such as fluoroelastomers, thermoplastic elastomers, and PTFE are improving the sealing capabilities in high-demand applications.

Challenges in the Seals Market

- Rising Raw Material Costs: The cost of raw materials, particularly elastomers and plastics, has been rising, which can increase the cost of manufacturing seals. This is a challenge for manufacturers who must balance performance requirements with cost-efficiency.

- Seal Failure and Maintenance Issues: Seal failure can lead to operational disruptions and safety hazards, particularly in industries like oil and gas and aerospace. Manufacturers must focus on improving the reliability and maintenance cycles of seals to reduce operational downtime and maintenance costs.

Conclusion

The Seals Market is witnessing growth driven by the increasing need for high-performance sealing solutions in industries such as automotive, aerospace, and energy. As technology continues to advance and industries push for better efficiency, sustainability, and safety, seals will continue to play a pivotal role in ensuring the performance and durability of systems across various sectors.

- Information Technology

- Office Equipment and Supplies

- Cars and Trucks

- Persons

- Books and Authors

- Tutorials

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Spellen

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness