Industrial Salt Market Forecast (2025–2032): Global Demand, Trends & Applications

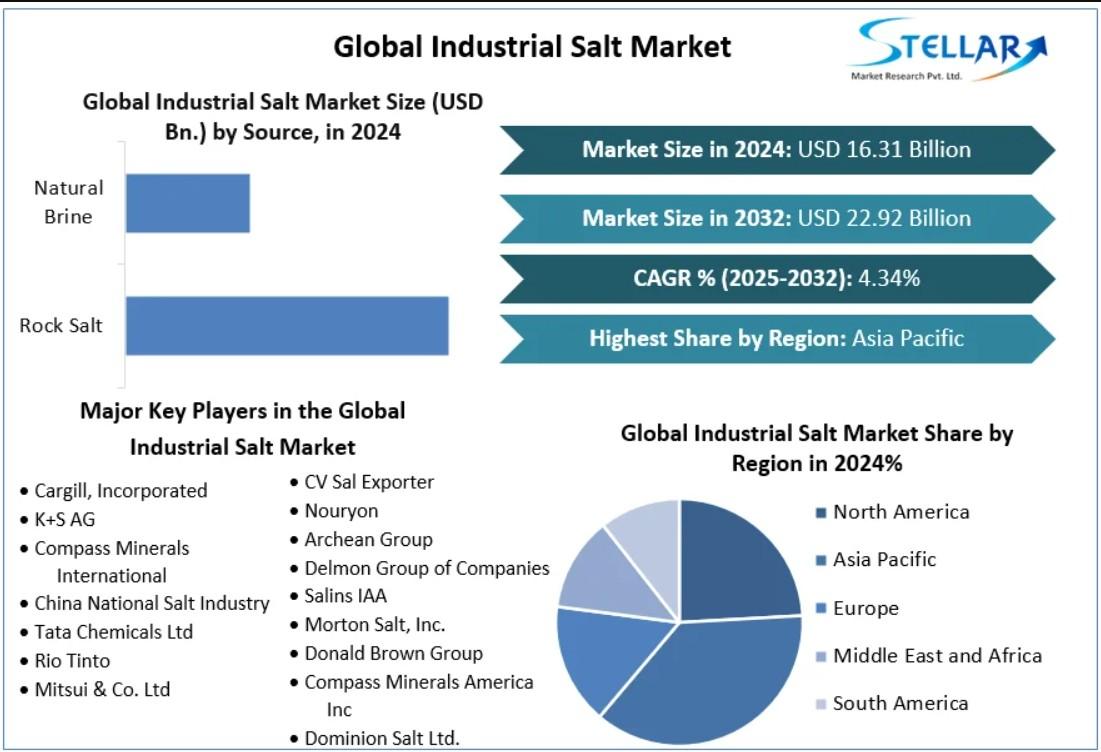

The Industrial Salt Market size was valued at USD 16.31 Billion in 2024 and the total industrial salt revenue is expected to grow at a CAGR of 4.34% from 2025 to 2032, reaching nearly USD 22.92 Billion by 2032 during the forecast period. The market is being driven by rising demand for salt in chemical processing, de-icing applications, and industrial water treatment.

Free Sample Copy: https://www.stellarmr.com/report/req_sample/industrial-salt-market/2450

1. Market Estimation & Definition

Industrial salt refers to high-volume, non-edible grade salt used across a variety of sectors such as chemical manufacturing, textile dyeing, water treatment, agriculture, and de-icing. Unlike table salt, industrial salt is utilized for its physical and chemical properties rather than for consumption.

Key types of industrial salt include:

-

Rock Salt (Halite)

-

Solar Salt (Evaporated Sea Salt)

-

Vacuum Salt (Purified)

Industrial salt plays a vital role in manufacturing processes like:

-

Chlor-alkali production (sodium hydroxide, chlorine, hydrogen)

-

Sodium carbonate manufacturing (soda ash)

-

Textile bleaching

-

Snow melting and road de-icing in cold climates

The market’s steady expansion is due to its indispensability in these core sectors.

Free Sample Copy: https://www.stellarmr.com/report/industrial-salt-market/2450

2. Market Growth Drivers & Opportunities

Expanding Chemical Industry

A major portion of industrial salt is used in the chlor-alkali industry to manufacture caustic soda, chlorine, and soda ash. These chemicals are critical inputs in plastics, paper, detergents, and glass manufacturing, fueling global salt consumption.

Increasing Demand for Water Treatment

As water pollution grows, many countries are turning to water softening and purification systems—which often rely on salt-based ion exchange processes—especially in urban infrastructure and industrial cooling systems.

De-Icing and Snow Control

In cold-weather countries like the U.S., Canada, Germany, and Russia, rock salt is extensively used for de-icing roads and highways during winter, driving seasonal spikes in demand.

Oil & Gas Industry Applications

Salt brine solutions are used in drilling operations, completion fluids, and well stimulation activities in the oil & gas sector. With global energy demands remaining high, salt usage in this sector is expected to grow steadily.

Growth of Textile and Leather Processing

Salt is used in dye-fixation and tanning processes, particularly in Asia-Pacific countries, where the textile and leather industries are expanding.

Opportunity in Renewable Energy Storage

Emerging research in molten salt thermal storage for concentrated solar power (CSP) systems is opening up a futuristic growth area for industrial salt.

3. Segmentation Analysis

By Source

-

Rock Salt

-

Natural Brine

-

Solar Salt

-

Vacuum Evaporated Salt

-

Rock Salt remains the most widely used form due to its availability and use in de-icing.

-

Solar salt, harvested via evaporation, is gaining popularity due to its cost-effectiveness in regions with high sun exposure.

-

Vacuum evaporated salt, with its high purity, is used in sensitive chemical and pharmaceutical processes.

By Manufacturing Process

-

Conventional Mining

-

Solar Evaporation

-

Vacuum Evaporation

-

Conventional mining dominates due to its scalability and use in rock salt production.

-

Solar evaporation is environmentally favorable and low-cost, suited to arid climates.

By Application

-

Chemical Processing

-

De-icing

-

Water Treatment

-

Oil & Gas

-

Agriculture

-

Others

-

Chemical processing is the largest segment, driven by the chlor-alkali and soda ash industries.

-

De-icing holds strong seasonal importance in North America and Europe.

-

Water treatment is growing fastest due to increasing concerns over industrial wastewater management.

4. Country-Level Analysis

🇺🇸 United States

-

The U.S. is one of the largest consumers of industrial salt, particularly for de-icing, consuming millions of tons annually during winters.

-

Strong demand also comes from the chemical industry, especially in states with large production of plastics and detergents.

-

With growing emphasis on water treatment infrastructure, the U.S. is investing in salt-based softening systems for both domestic and industrial use.

🇩🇪 Germany

-

Germany relies heavily on industrial salt for its chemical manufacturing, especially in the Rhineland and Bavaria, where leading industrial parks are located.

-

Germany also uses industrial salt for road safety, with efficient logistics for rock salt distribution during winter.

-

There is a trend toward sustainable sourcing and brine extraction methods, driven by stringent EU environmental regulations.

5. Commutator (Competitive) Analysis

The industrial salt market is moderately fragmented with several global and regional players. Competition is shaped by:

-

Volume capacity and supply chain efficiency

-

Cost control and pricing strategies

-

Purity and quality consistency

-

Geographical access to mines and evaporation fields

Key Players:

-

Cargill, Inc.

-

K+S AG

-

Compass Minerals International, Inc.

-

Tata Chemicals Ltd.

-

INEOS Enterprises

-

Morton Salt (Kissner Group)

-

China National Salt Industry Corporation

-

Exportadora de Sal S.A.

-

Akzo Nobel Salt

-

Dominion Salt Limited

Strategic Highlights:

-

Cargill focuses on integrated logistics and snow control salt for North America.

-

K+S AG leverages deep mining operations and strong EU presence.

-

Tata Chemicals serves both industrial and consumer segments with high-purity vacuum salt.

-

Compass Minerals is expanding digital monitoring of salt usage in de-icing to optimize city budgets.

-

Exportadora de Sal (Mexico) is a leading supplier to Asian chemical producers, leveraging solar evaporation.

6. Conclusion

The Industrial Salt Market is foundational to modern industry, from chlorine production and oil drilling to textile dyeing and public safety. With applications touching almost every aspect of industrial manufacturing and infrastructure maintenance, salt’s future remains solid.

As the market heads toward USD 20.63 billion by 2030, key trends include:

-

Growing focus on sustainable mining and salt harvesting

-

Innovation in renewable energy applications (molten salt for CSP)

-

Rising demand from emerging economies for water purification and industrial growth

-

Potential for IoT in monitoring salt usage in municipal de-icing systems

With regional players scaling up to meet global quality standards and MNCs optimizing logistics and sustainability, the industrial salt market is poised to crystallize new opportunities across the globe.

About Us:

Stellar Market Research is a leading India-based consulting firm delivering strategic insights and data-driven solutions. With 119 analysts across 25+ industries, the company supports global clients in achieving growth through tailored research, high data accuracy, and deep market intelligence, serving Fortune 500 companies and maintaining strict client confidentiality.

Address

Phase 3, Navale IT Zone, S.No. 51/2A/2, Office No. 202, 2nd floor, Near, Navale Brg, Narhe, Pune, Maharashtra 411041

sales@stellarmr.com

Mobile

+91 9607365656

- Information Technology

- Office Equipment and Supplies

- Cars and Trucks

- Persons

- Books and Authors

- Tutorials

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Игры

- Gardening

- Health

- Главная

- Literature

- Music

- Networking

- Другое

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness