Milliseconds to Save a Life: The Evolving Role of Airbag Inflators in Automotive Safety

A blink takes 300 milliseconds. But in a head-on collision, an airbag inflator must deploy within just 20 milliseconds—faster than the blink of an eye, faster than most drivers can react. That tiny explosion, perfectly timed and precisely calibrated, is what often makes the difference between life and death.

To get free sample, Click Here: https://www.stratviewresearch.com/Request-Sample/124/automotive-airbag-inflators-market.html#form

Behind every airbag’s life-saving inflation is a compact yet critical component: the airbag inflator. It’s not just about pressure and gas anymore—it’s about intelligence, reliability, and global trust in a world increasingly focused on automotive safety.

The Problem: Evolving Safety Expectations Meet a Changing Vehicle Landscape

As governments, insurers, and consumers push for safer cars, airbags are now standard across virtually every segment—from compact hatchbacks to electric SUVs.

But while airbags have become ubiquitous, airbag inflator technology has had to evolve rapidly to meet new challenges:

-

⚠️ Global vehicle safety regulations now demand multiple airbags per vehicle (front, side, curtain, knee, seatbelt-integrated).

-

⚡ EVs and autonomous vehicles require rethinking sensor placement and inflation directionality due to altered cabin designs.

-

🧠 Advanced crash sensors and AI in vehicles require inflators to work with greater precision and at variable speeds.

-

🚫 Historical product recalls (e.g., Takata) have heightened scrutiny on inflator reliability, propellant chemistry, and lifecycle degradation.

Today’s airbag inflator isn’t just a gas generator. It’s a mission-critical safety device, engineered to deliver controlled explosions with microsecond precision in any temperature, crash angle, or deployment sequence.

The Agitation: The Cost of Failure Is No Longer Tolerable

Over the last decade, inflator failures have resulted in:

-

💥 Massive global recalls affecting over 100 million vehicles

-

⚖️ Billions in legal settlements and class-action suits

-

🔬 A reevaluation of propellant types, material sourcing, and testing standards

This has pushed automakers and regulators toward:

-

🌡️ Stricter environmental exposure testing (heat, humidity, cold cycles)

-

🔋 Inflator compatibility with electrified and compact architectures

-

📦 Modular, multi-stage inflator systems for advanced protection

-

🧪 Inert gas alternatives to replace ammonium nitrate-based designs

The message is clear: there is zero margin for error in the inflator supply chain.

The Market Response: Precision, Performance, and Compliance

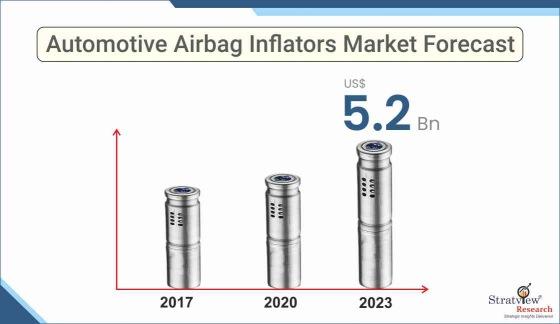

According to Stratview Research, the automotive airbag inflators market size was estimated at USD 4.2 billion in 2017 and is likely to grow at a CAGR of 4.2% during 2018-2023 to reach USD 5.2 billion in 2023.

This growth is fueled by:

-

🚗 Higher vehicle production volumes, especially in Asia-Pacific

-

📈 Increased airbag penetration per vehicle across both developed and emerging markets

-

🛻 Demand for side-impact and rollover airbags in SUVs and pickups

-

⚙️ Integration of smart sensors and AI, requiring inflators to respond to precise crash data and deploy in multiple stages

Types of Inflators Shaping the Market

-

Pyrotechnic Inflators

-

Traditional and cost-effective

-

Generate gas through a chemical reaction

-

Used in frontal and some side airbags

-

-

Hybrid Inflators

-

Combine stored gas and pyrotechnic charge

-

Allow more controlled and multi-stage deployment

-

Popular in curtain and knee airbags

-

-

Stored Gas Inflators

-

Purely compressed inert gas

-

Common in low-deployment-force applications (e.g., pedestrian protection)

-

-

Multi-Stage Inflators

-

Deploy in variable phases based on crash severity and occupant position

-

Essential for vehicles with advanced occupant sensing systems

-

Who’s Leading the Market?

Top inflator manufacturers include:

-

Autoliv – Global leader in airbag modules and inflator integration

-

ZF Friedrichshafen AG (formerly TRW) – Offers hybrid and adaptive inflators for OEM platforms

-

Daicel Corporation – Specializes in inflators and gas-generating agents

-

Nihon Plast, Hyundai Mobis, and Joyson Safety Systems – Key players in the Asia-Pacific market, with strong OEM partnerships

With growing focus on regional supply chains, inflator manufacturing is becoming more localized, especially in India, Thailand, and Eastern Europe to support nearby assembly plants.

Strategic Takeaways

-

Inflators are no longer generic components—they are precision safety instruments engineered for crash type, occupant size, and vehicle architecture.

-

As EV platforms evolve and passenger cabins change shape, inflators will need to adapt to new trigger logic and geometry.

-

Companies that can deliver lightweight, multi-stage, compliant inflators at scale—with advanced diagnostics and QA systems—will lead in the next safety-focused decade.

-

Regulatory harmonization across UN, US-NCAP, Euro NCAP, and China-NCAP is driving global standards and reducing regional variances in inflator specs.

- Information Technology

- Office Equipment and Supplies

- Cars and Trucks

- Persons

- Books and Authors

- Tutorials

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Spiele

- Gardening

- Health

- Startseite

- Literature

- Music

- Networking

- Andere

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness