Shielding the Core: How Coatings Are Powering the Future of Aero-Engines

Every minute, more than 100,000 aircraft take off, cruise, and land somewhere across the globe. And at the heart of each flight lies a modern marvel—the aero-engine, where temperatures often exceed 1,500°C, pressures soar, and tolerances are razor-thin.

To get free sample, CLick Here: https://www.stratviewresearch.com/Request-Sample/471/aero-engine-coatings-market.html#form

In such an unforgiving environment, it's not just design or material that sustains performance—it’s protection. And that protection comes from a science few passengers ever think about: engine coatings.

As the aerospace industry eyes greater fuel efficiency, sustainability, and engine longevity, the aero-engine coatings market is undergoing a quiet but powerful revolution.

The Problem: Higher Performance Equals Higher Thermal Stress

Modern aero-engines are being pushed to new extremes:

-

Higher thrust-to-weight ratios

-

Leaner fuel burn for emissions compliance

-

Lighter turbine materials to reduce mass

-

Greater operating temperatures for fuel efficiency gains

But this evolution comes at a cost—thermal fatigue, oxidation, corrosion, and erosion of key components such as turbine blades, combustor liners, and nozzles.

Without advanced protective coatings, these parts can degrade faster, reducing engine lifespan, increasing maintenance intervals, and ultimately risking in-flight reliability.

The Agitation: Operating in the Red Zone

Aero-engine environments present a perfect storm of degradation factors:

🌡️ Thermal Cycling: Engines heat up and cool down thousands of times per year, inducing micro-cracks and stress fractures.

💨 Oxidation and Hot Corrosion: The combination of high temperatures and airborne salts (especially in marine and desert regions) leads to surface degradation.

🌪️ Erosion: Ingested particles—dust, ice, sand—wear down uncoated blades, vanes, and liners.

⚙️ Fuel Composition Shifts: The rise of Sustainable Aviation Fuel (SAF) and hydrogen propulsion is introducing new combustion chemistries that challenge traditional coatings.

Each factor can compromise turbine efficiency and spike maintenance costs. In high-bypass turbofan engines used in commercial aviation, even a 1% reduction in thermal barrier coating effectiveness can increase fuel consumption and emissions measurably.

The Market Response: Coatings That Can Withstand the Sky’s Wrath

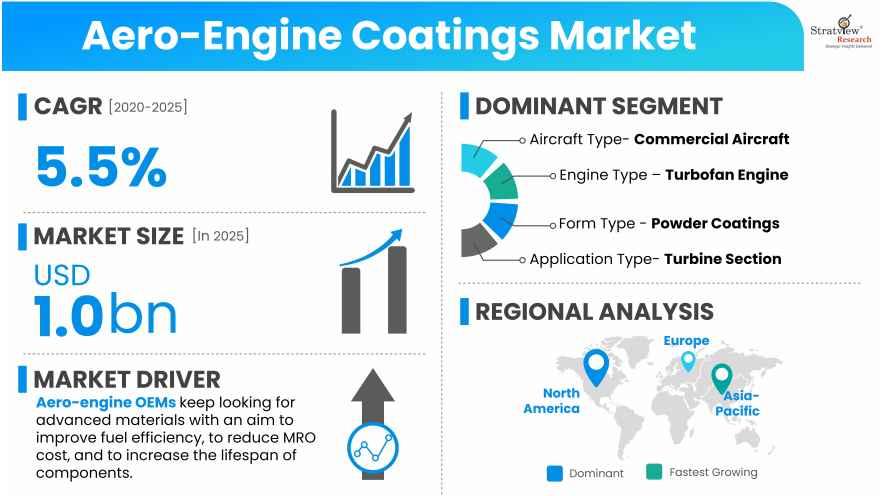

According to Stratview Research, The global aero-engine coatings market size was estimated at USD 0.82 billion in 2019 and is likely to grow at a CAGR of 5.5% during 2020-2025 to reach USD 1.0 billion by 2025.

This growth is propelled by:

✈️ Rising commercial aircraft deliveries to meet global air travel demand

⚙️ Increased use of next-gen engines like LEAP, GEnx, and PW1000G that require high-performance coatings

🔧 Aftermarket maintenance and MRO growth, especially for aging fleets

🌱 Focus on efficiency and sustainability, which requires keeping engines cleaner, longer

What Are These Coatings—and How Do They Work?

Aero-engine coatings fall into three primary categories:

-

Thermal Barrier Coatings (TBCs)

-

Typically ceramic-based (e.g., yttria-stabilized zirconia)

-

Applied via air plasma spraying (APS) or electron beam physical vapor deposition (EB-PVD)

-

Used in high-temperature zones to insulate metal substrates

-

-

Bond Coats

-

Serve as an adhesion layer between TBC and base metal

-

Made of MCrAlY alloys (M = Ni or Co) to prevent oxidation

-

-

Abradable and Erosion-Resistant Coatings

-

Found in compressors, seals, and casing linings

-

Help maintain tight clearances without damaging rotating parts

-

Often polymer, ceramic, or metal matrix composites

-

Who’s Leading the Market?

Major players dominating the aero-engine coatings value chain include:

-

Praxair Surface Technologies (now part of Linde)

-

Oerlikon Group

-

Cincinnati Thermal Spray

-

APS Materials

-

Flame Spray Technologies

-

Chromalloy and Hohman Plating (for repair/MRO-focused coatings)

OEMs like GE Aviation, Rolls-Royce, Safran, and Pratt & Whitney are also developing in-house coating capabilities to enhance design-performance integration.

What’s Changing?

🧠 Smart Coatings: Research is advancing into self-healing or temperature-indicating coatings that offer predictive maintenance cues.

🌱 Eco-Friendly Deposition Techniques: New approaches like cold spraying reduce energy use and VOC emissions during coating.

⚡ Additive-Compatible Coatings: With growing use of 3D printed engine components, coatings must adapt to new surface morphologies and porosities.

🔄 Aftermarket Upgrades: Airlines and MROs are increasingly retrofitting older engines with advanced coatings to extend life and improve efficiency.

Strategic Takeaways

-

Aero-engine coatings are no longer optional—they're mission-critical performance enablers in the age of sustainable aviation.

-

As engines operate hotter and longer, coatings must do more than protect—they must enable design innovation and extend operating intervals.

-

Players offering customized, multi-functional coatings with MRO-ready scalability will lead the market.

-

With hydrogen propulsion and SAF adoption on the horizon, the next generation of coatings must be chemistry-adaptable and thermally tougher than ever.

- Information Technology

- Office Equipment and Supplies

- Cars and Trucks

- Persons

- Books and Authors

- Tutorials

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Juegos

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness