The Invisible Ingredient Driving Polymer Precision

On the factory floor, where molten polymers are extruded at blistering speeds into films, pipes, wires, and sheets, every second counts — and every surface defect costs. While operators monitor torque, pressure, and line speed, there’s one critical ingredient working silently in the background to keep production smooth: the polymer processing aid (PPA).

To get free sample, Click Here: https://www.stratviewresearch.com/Request-Sample/572/polymer-processing-aid-market.html#form

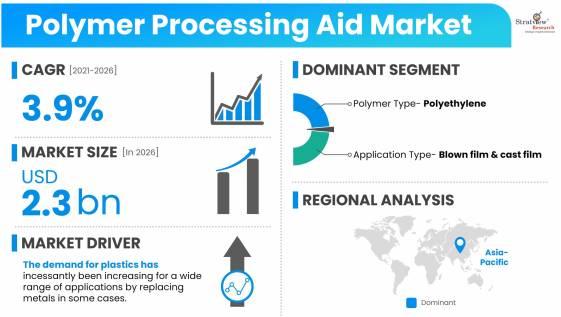

According to stratview research, the polymer processing aid market was estimated at USD 1.8 billion in 2020 and is likely to grow at a CAGR of 3.9% during 2021–2026 to reach USD 2.3 billion in 2026.

It doesn’t show up in marketing brochures or packaging labels. But without it, manufacturers face sharkskin defects, die buildup, surface haze, and lower throughput. A compound added in tiny doses — sometimes as low as 100 parts per million — can be the difference between a flawless extrusion run and a production disaster.

In short, PPAs are the unsung heroes of high-performance polymer processing.

What Are Polymer Processing Aids?

PPAs are specialty additives — often fluoropolymer- or silicone-based — designed to enhance the melt flow behavior of polymers during high-shear processing. They help reduce:

- Melt fracture and surface roughness

- Pressure build-up in dies and extruders

- Downtime during material transitions

- Energy consumption and wear on equipment

And the best part? They don’t change the final polymer’s mechanical properties. That’s why they’ve become indispensable in producing LLDPE films, HDPE pipes, PVC cables, and even bioplastic blends.

Why Are They More Important Than Ever?

The plastics world is under pressure — literally and figuratively:

- Faster production lines demand smoother flow and minimal interruptions.

- Thinner films and lighter parts require exceptional surface quality.

- Recycled and bio-based resins bring inconsistency that needs to be stabilized.

- Global regulations are phasing out traditional fluorinated chemicals (PFAS), forcing the industry to find new formulations — fast.

In this climate, PPAs aren’t just problem solvers. They’re strategic process enablers — improving efficiency, reducing waste, and helping manufacturers meet sustainability targets.

Today, whether you’re making multi-layer food packaging in India or automotive wire sheathing in Germany, chances are your product quality — and your bottom line — depends on a nearly invisible additive doing an extraordinary job.

- Information Technology

- Office Equipment and Supplies

- Cars and Trucks

- Persons

- Books and Authors

- Tutorials

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Jocuri

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Alte

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness