Structural Core Materials Market Strengthens with Growth in Lightweight Composite Applications Across Key Industries

The Structural Core Materials Market is experiencing steady expansion, driven by the rising demand for lightweight, high-strength, and durable materials in aerospace, automotive, wind energy, and marine industries. These materials—such as foam, honeycomb, and balsa cores—serve as the central layer in composite sandwich structures, significantly enhancing stiffness and reducing overall weight without compromising mechanical performance.

To get free sample, Register Here: https://www.stratviewresearch.com/Request-Sample/486/structural-core-materials-market.html#form

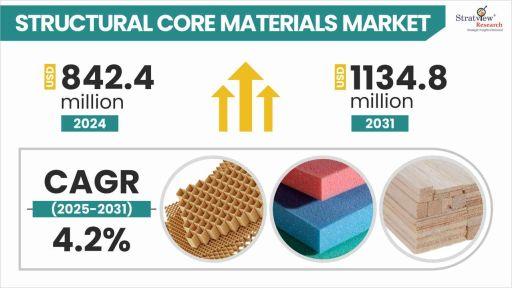

The structural core materials market was valued at US$ 842.4 million in 2024 and is likely to grow at a CAGR of 4.2% in the long run to reach US$ 1134.8 million in 2031.

Market Drivers:

Several key factors are fueling the growth of the structural core materials market:

- Surging Demand for Lightweight Structures: The push for fuel efficiency and emissions reduction is accelerating the adoption of lightweight core materials in transportation and energy sectors.

- Growth in Aerospace and Defense: Aircraft OEMs increasingly use honeycomb and foam cores in interior panels, flight control surfaces, and fuselage components to meet performance and safety standards.

- Renewable Energy Expansion: Wind turbine manufacturers use structural cores in rotor blades to improve stiffness-to-weight ratios and withstand high loads.

- Innovation in Material Technology: Advances in recyclable cores, hybrid structures, and fire-resistant formulations are expanding use in construction and electric vehicles.

Key Players

Here is the list of the Top Players (Based on Alphabetical Order)

- 3A Composites Gmbh (Schweiter Technologies AG)

- Gurit Holdings AG

- Diab International AB

- Armacell International S.A.

- Baoding Weise New Materials Technology Co., Ltd. (China)

- Changzhou Tiansheng New Materials Co., Ltd. (China)

- Evonik Industries AG

- Maricell S.r.l.

Key Applications:

- Aerospace: Utilized in flooring, interior panels, bulkheads, and secondary structures to reduce aircraft weight and improve efficiency.

- Wind Energy: Core materials are essential for long rotor blades, enabling increased energy output and structural integrity.

- Marine: Used in hulls, decks, and superstructures of boats and yachts to enhance buoyancy and performance.

- Automotive: Applied in body panels, hoods, and trunk lids in EVs and luxury cars to reduce weight while maintaining crash safety.

- Construction: Used in architectural panels, facades, and sandwich walls for thermal insulation and structural support.

Recent Developments:

- In 2024, Diab Group introduced a new range of recyclable PET foam cores targeting wind energy and marine sectors.

- Gurit expanded its honeycomb core manufacturing capacity in Asia to meet growing demand from aerospace and rail industries.

- 3A Composites launched high-performance balsa-foam hybrid cores with enhanced impact resistance and fire retardancy for advanced mobility platforms.

Future Outlook:

Demand will be fueled by the proliferation of electric vehicles, growth in offshore wind projects, and increased adoption of composite materials in infrastructure. Sustainability trends will further drive innovations in bio-based, recyclable, and low-emission core materials.

As lightweighting becomes a top priority across multiple sectors, structural core materials will remain essential to the design of efficient, resilient, and sustainable next-generation products.

- Information Technology

- Office Equipment and Supplies

- Cars and Trucks

- Persons

- Books and Authors

- Tutorials

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Juegos

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness