The Role of Custom Metal Fabrication in Modern Industry: From Prototyping to Production

Modern industry is evolving faster than ever, with companies across sectors seeking more efficient, flexible, and innovative ways to build the products and infrastructure of tomorrow. At the center of this progress lies custom metal fabrication—a vital process that turns raw metals into the precision parts, assemblies, and structures that keep our world running smoothly.

From the cars we drive and the buildings we work in to the tools and machines powering factories, custom metal fabrication is everywhere. In this article, we’ll explore how this discipline supports industries at every stage, why it’s so important, and how partnering with a quality fabricator like Kirmell can help businesses achieve success from initial concept through to full-scale production.

What Is Custom Metal Fabrication?

Custom metal fabrication is the art and science of shaping, cutting, joining, and finishing metals to meet a specific need. Unlike mass-produced, one-size-fits-all parts, custom fabrication involves tailoring every detail—from material selection to final finish—to the unique requirements of a particular project.

Typical processes in custom metal fabrication include:

-

Cutting: Using laser, plasma, or waterjet technology to achieve precise shapes and sizes.

-

Forming: Bending, rolling, or pressing sheet metal and bars to the required profile.

-

Welding & Assembly: Joining components with strong, reliable welds for durability and strength.

-

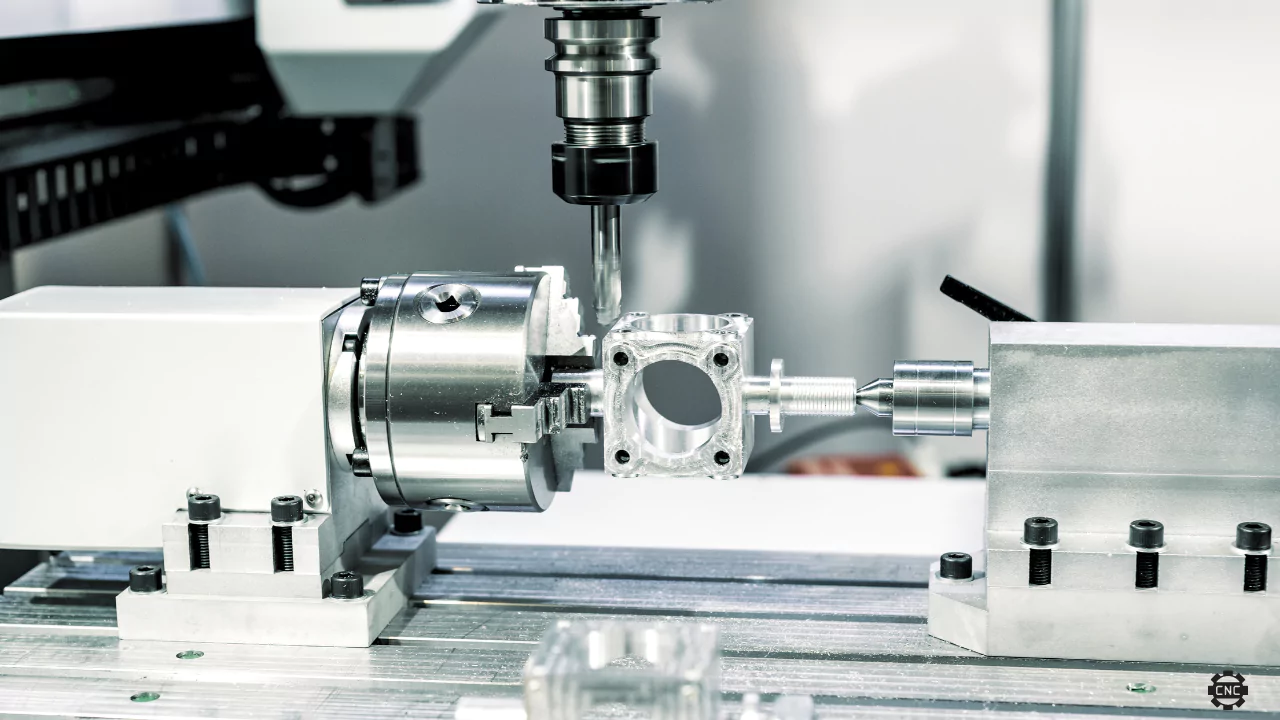

Machining: CNC milling, turning, and drilling for high-precision parts.

-

Finishing: Powder coating, painting, polishing, or other treatments for aesthetics and protection.

From Prototype to Production: Supporting Every Stage

1. Prototyping and Design

One of the most important roles of custom metal fabrication is enabling rapid prototyping. When an engineer or designer comes up with a new product, they need to see how it performs in the real world. Quick-turn prototypes allow for design tweaks, functional testing, and material evaluation—essential steps before full-scale production.

Fabricators like Kirmell work closely with clients in the early stages, offering design advice, recommending suitable materials, and helping identify cost-effective manufacturing methods. This collaborative approach leads to better products and faster time-to-market.

2. Small Batch and One-Off Production

Not every project requires thousands of identical parts. Sometimes, a business needs a limited run for testing, replacement, or specialty applications. Custom metal fabrication shines in these cases, offering the flexibility to produce short runs or even one-off pieces with the same quality and precision as large orders.

3. Full-Scale Production

Once a design is finalized and demand increases, custom metal fabricators are ready to scale up. With advanced CNC machinery and automated processes, shops can handle large orders efficiently, maintaining tight tolerances and consistent quality throughout.

Industries That Rely on Custom Metal Fabrication

The value of custom metal fabrication stretches across almost every industry:

-

Automotive: Chassis parts, brackets, enclosures, and heat shields.

-

Construction: Beams, columns, cladding, stairs, and handrails.

-

Architecture: Decorative panels, balustrades, and custom facades.

-

Aerospace: Lightweight frames, structural components, and housings.

-

Manufacturing: Machine parts, guards, conveyor systems, and workstations.

-

Energy: Wind turbine housings, solar panel frames, and pipeline supports.

-

Medical: Surgical tools, equipment housings, and custom supports.

Wherever reliability, precision, and custom solutions are required, metal fabrication delivers.

The Benefits of Custom Metal Fabrication

1. Perfect Fit and Function

Custom fabrication ensures that every component meets the exact needs of the client, integrating seamlessly with existing systems and requirements.

2. Material Flexibility

From stainless steel and aluminum to copper, brass, and specialty alloys, the right material can be chosen for strength, weight, corrosion resistance, or aesthetics.

3. Design Innovation

With advanced tools like CAD software, laser cutters, and CNC machines, even complex shapes and unique geometries are possible.

4. Quality and Durability

Experienced fabricators use quality checks and rigorous processes to deliver parts that stand up to real-world use.

5. Cost-Effective Solutions

By working closely with clients on design, material selection, and production methods, fabricators help avoid costly mistakes and wasted materials.

What to Look for in a Metal Fabrication Partner

Choosing the right fabrication partner can make all the difference. Here’s what to consider:

-

Expertise: Look for a team with experience in your industry and the technical know-how to solve challenges.

-

Modern Equipment: Advanced machinery delivers better quality, faster turnaround, and competitive pricing.

-

Custom Service: Your needs are unique—your fabricator should offer personalized advice, clear communication, and support throughout the process.

-

Quality Assurance: Reliable inspection and testing at every stage mean you get exactly what you ordered.

-

Full-Service Capabilities: From design assistance to finishing and delivery, a one-stop shop saves time and simplifies your project.

Why Work With Kirmell?

At Kirmell, we believe every project deserves the same level of care—whether it’s a prototype, a specialty one-off, or a high-volume production run. Our skilled engineers and fabricators work with advanced technology and a passion for quality to deliver custom metal solutions you can trust.

From sheet metal fabrication and CNC machining to welding, finishing, and assembly, our team is ready to help you succeed at every stage. We’re committed to delivering on time, on budget, and to your exact specifications—no matter how complex your project may be.

Conclusion

Custom metal fabrication is the backbone of modern industry, providing the flexibility, precision, and reliability needed to move from concept to completion. Whether you’re launching a new product, upgrading your facility, or tackling a complex build, choosing the right fabrication partner is essential for success.

Ready to get started? Discover how Kirmell can support your project at every stage—visit Kirmell to learn more or request a consultation.

- Information Technology

- Office Equipment and Supplies

- Cars and Trucks

- Persons

- Books and Authors

- Tutorials

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Games

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness