Modern Grids, Smarter Materials: The Rise of Hollow Core Composite Insulators

Introduction

The global power industry is undergoing a radical transformation, demanding components that are smarter, stronger, and more resilient. Hollow core composite insulators—key components in substations, circuit breakers, and bushings—are emerging as critical enablers of this transition.

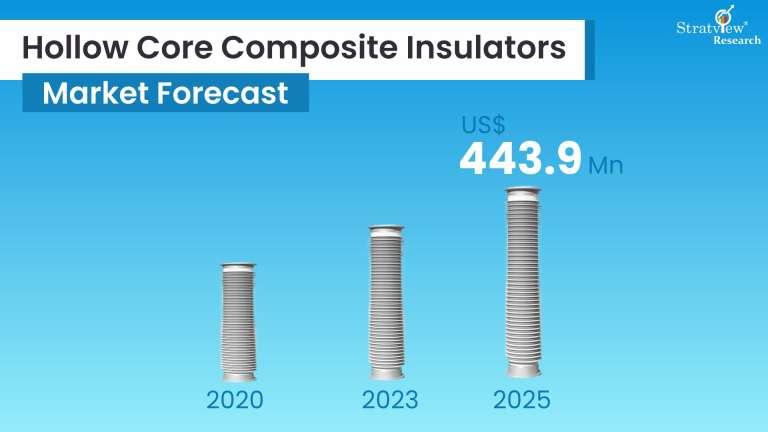

According to Stratview Research hollow core composite insulators market is projected to grow at an excellent rate during the forecast period 2020–2025, reaching an estimated value of US$ 443.9 million by 2025.

What Sets Composite Insulators Apart?

Unlike traditional ceramic and porcelain insulators, composite types are built using advanced resin systems and fiberglass rods encased in silicone rubber. This design offers:

-

Improved flashover performance under contamination

-

Resistance to UV degradation and acid rain

-

Compact and lightweight form, ideal for compact substations

-

Quick installation, especially in retrofit projects

Why Now?

-

Climate Resilience: With wildfires, storms, and floods increasing in frequency, utilities need insulators that won't crack, shatter, or fail in extreme conditions.

-

High-Voltage Upgrades: As utilities push toward higher voltage lines (≥400kV) to minimize transmission losses, the demand for hollow core composite insulators capable of withstanding elevated stresses is accelerating.

-

Smart Grid Expansion: Composite insulators with built-in monitoring capabilities are being explored in smart grid applications to provide real-time health diagnostics.

Market Challenges

-

Procurement Hesitancy: For utilities used to porcelain, switching to composite insulators requires education and performance data validation.

-

Technological Barriers: Not all regions have access to high-end manufacturing capabilities, which can limit adoption of composite-based designs.

-

Counterfeit Risks: Low-quality replicas in price-sensitive markets can damage trust in composite solutions unless regulated.

To get free sample, Register Here: https://www.stratviewresearch.com/Request-Sample/813/hollow-core-composite-insulators-market.html#form

Who’s Leading the Charge?

Key players like Hitachi Energy, TE Connectivity, MacLean Power Systems, and Seves Group are investing heavily in design optimization and material innovation. Strategic collaborations between utilities and OEMs are also fostering faster adoption.

Future Outlook

The integration of IoT-based sensors into composite insulators could be a game-changer, enabling condition-based maintenance and early fault detection. Moreover, with a rising push toward renewable transmission corridors, demand for hollow core composite insulators is only expected to climb.

Conclusion

In the race to build smarter, safer, and more sustainable grids, hollow core composite insulators are quickly moving from being optional upgrades to essential components. For power utilities looking to future-proof their systems, the time to invest in composite insulation technology is now.

- Information Technology

- Office Equipment and Supplies

- Cars and Trucks

- Persons

- Books and Authors

- Tutorials

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Juegos

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness