Machine Tool Bearings Market: Critical Components for Precision and Performance

Machine tool bearings are crucial components in ensuring the accuracy, precision, and efficiency of machine tools. These bearings support rotating parts in machining systems, reducing friction and ensuring smooth motion, which is essential for the production of high-quality components in industries such as automotive, aerospace, and electronics. As the demand for more advanced and precise manufacturing processes grows, the need for high-performance machine tool bearings continues to rise.

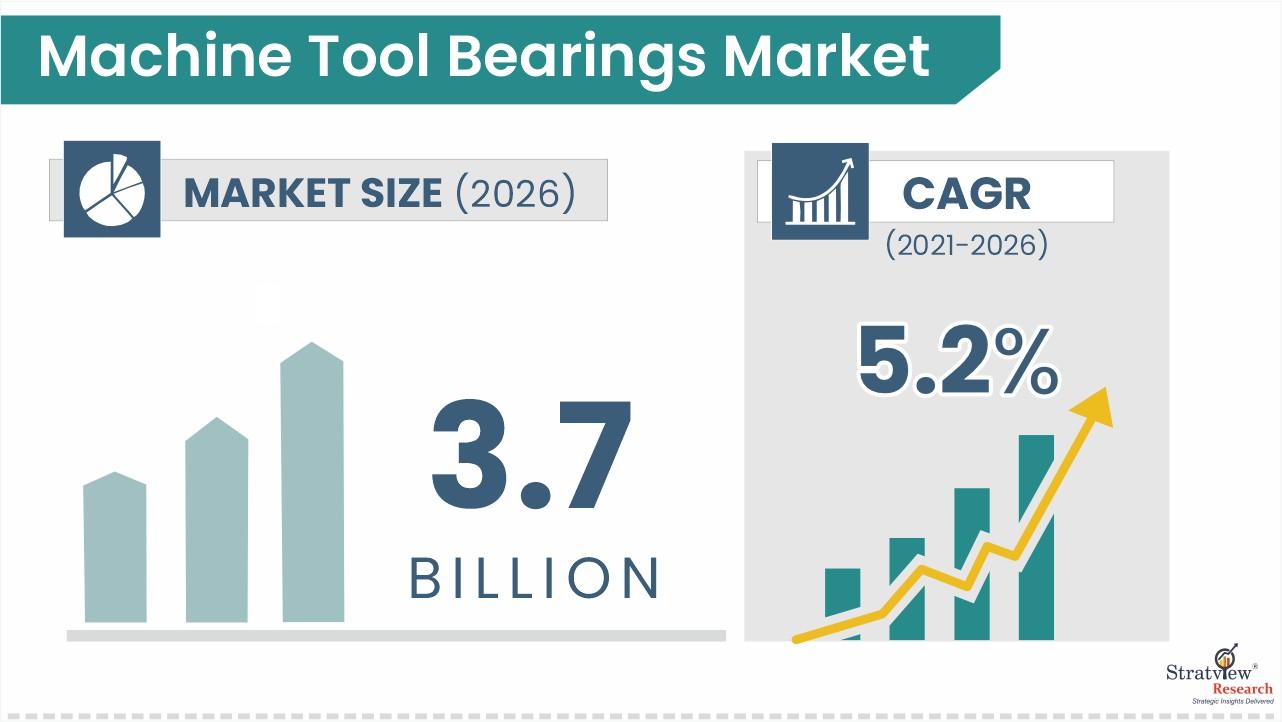

Stratview Research forecasts the Machine Tool Bearings Market to grow at a CAGR of 5.2% from 2021 to 2026, reaching USD 3.7 billion by 2026. This growth is driven by advancements in machine tool technologies, increased industrial automation, and the need for higher precision in manufacturing.

Want to know more about the market scope?

https://stratviewresearch.com/Request-Sample/1964/machine-tool-bearings-market.html#form

What Are Machine Tool Bearings?

Machine tool bearings are mechanical components that reduce friction and support the rotating or moving parts of machine tools. These bearings are designed to withstand heavy loads and high speeds while ensuring the smooth operation of the machine. The two most common types of machine tool bearings are ball bearings and roller bearings, with each type offering distinct advantages depending on the application.

Applications of Machine Tool Bearings

- CNC Machines: Machine tool bearings are extensively used in computer numerical control (CNC) machines, which are critical in high-precision manufacturing. Bearings help CNC machines achieve the fine tolerances needed in industries like aerospace and automotive.

- Lathe Machines: Lathe machines rely on machine tool bearings to support the spindle and ensure smooth rotational motion. These machines are used for cutting, shaping, and finishing parts in a wide range of industries.

- Milling Machines: Milling machines, which are used for shaping materials, require machine tool bearings to maintain the precision of their cutting tools and spindle, ensuring high-quality finishes on machined components.

Market Drivers for Machine Tool Bearings

- Increasing Automation in Manufacturing: The global push toward industrial automation is a key driver for the machine tool bearings market. As manufacturers look for more efficient, precise, and automated production lines, the demand for high-quality machine tools—and consequently, machine tool bearings—grows.

- Growth in the Aerospace and Automotive Sectors: Both the aerospace and automotive industries require high-precision machining for components like engine parts, transmissions, and landing gears. As these sectors grow, so does the demand for machine tool bearings that provide the precision and durability required in machining critical components.

- Technological Advancements in Machine Tools: The development of advanced CNC machines and high-speed machining techniques requires better-performing machine tool bearings. Bearings that can withstand higher speeds, temperatures, and loads are in demand to meet the evolving requirements of modern machine tools.

Challenges in the Machine Tool Bearings Market

- High Maintenance Costs: Machine tool bearings are subject to wear and tear due to their constant exposure to high speeds and heavy loads. This necessitates regular maintenance and replacement, leading to higher operational costs for manufacturers.

- Material Wear and Durability: The materials used in machine tool bearings must be able to withstand high friction and extreme conditions. Ensuring the longevity of bearings in harsh machining environments is a significant challenge for manufacturers.

Conclusion

The Machine Tool Bearings Market is set to experience steady growth, driven by advancements in manufacturing technology, increased industrial automation, and the rising demand for precision and efficiency in machining processes. As industries such as aerospace, automotive, and electronics continue to expand, the role of high-performance machine tool bearings will remain crucial in ensuring the smooth operation of modern manufacturing systems.

- Information Technology

- Office Equipment and Supplies

- Cars and Trucks

- Persons

- Books and Authors

- Tutorials

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Games

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness