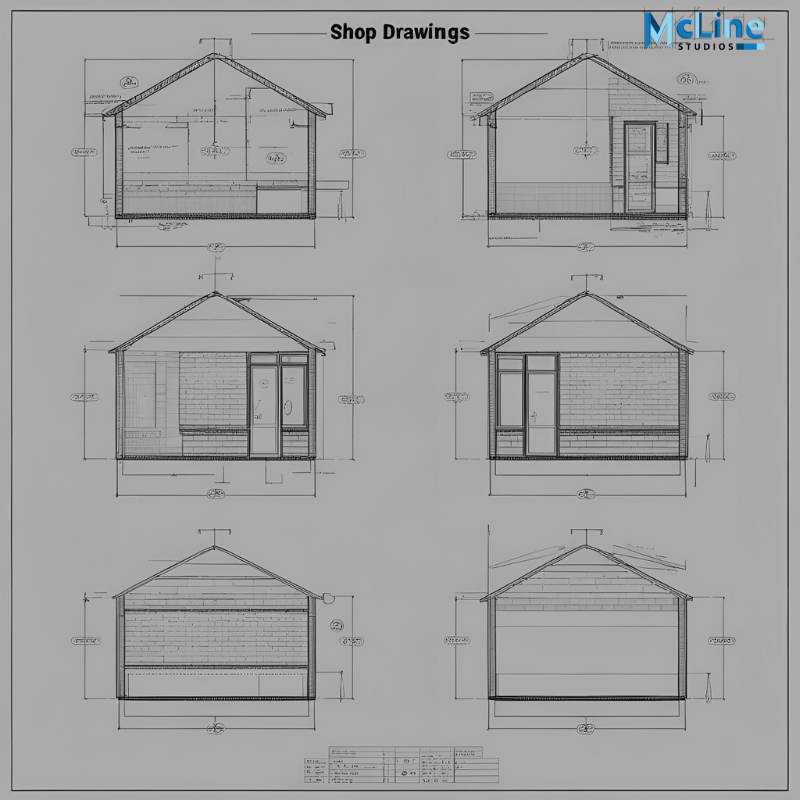

Why Contractors Rely on Detailed Shop Drawings for Smooth Execution?

In the fast-paced world of construction, precision and clarity are key to avoiding costly delays and rework. This is where detailed shop drawings play a crucial role. Unlike general design drawings, shop drawings provide contractors with a deeper, more accurate representation of how specific elements, such as millwork, HVAC systems, structural components, or electrical layouts, will be fabricated and installed.

These drawings bridge the gap between architectural intent and on-site execution, serving as a roadmap that ensures all stakeholders are on the same page.

By relying on well-prepared shop drawings, contractors can streamline the construction process, coordinate more effectively with various trades, and minimize the risk of errors, ultimately contributing to a smoother and more successful project delivery.

The Role of Shop Drawings in Construction Projects

Shop drawings are an important part of any construction project. They are detailed drawings made by contractors, manufacturers, or suppliers. These drawings show how different parts of the building will be made, installed, and connected. Shop drawings are more detailed than regular design drawings made by architects or engineers.

The main role of shop drawings is to give clear instructions to the workers. They show the exact sizes, materials, and installation methods for things like windows, doors, cabinets, steel frames, and mechanical parts. This helps avoid confusion on the site and reduces mistakes.

Shop drawings also help in coordination. In large projects, many teams work at the same time. With shop drawings, teams can make sure their work fits with others. For example, the HVAC system can be designed to fit with the ceiling and lighting plans.

Another important role of shop drawings is getting approvals. Before building starts, shop drawings are sent to the architect or engineer for review. They check if everything meets the design and safety standards. Once approved, work can move ahead with confidence.

In short, shop drawings are key to turning design ideas into real structures. They improve communication, reduce errors, and ensure that everything fits and works well together. Without shop drawings, construction projects could face delays, cost overruns, and safety issues. That’s why they are an essential tool in the construction process.

Why Detailed Shop Drawings are Crucial for Contractors

Detailed shop drawings are essential tools for contractors. They show exactly how different parts of a building or project should be made and installed. Unlike basic design drawings, shop drawings include all the little details that make construction work smoother and faster.

For example, these drawings show exact measurements, materials, and how parts connect. This helps contractors avoid mistakes on-site. When everything is clear from the beginning, there is less confusion during construction. This means fewer delays and reduced costs.

Shop drawings also help in planning. Contractors can see ahead of time what materials they need and how long certain tasks might take. It becomes easier to schedule workers and manage time well.

Another big benefit is better communication. Shop drawings are a common reference point for everyone contractors, engineers, architects, and suppliers. This keeps everyone on the same page and reduces the chances of misunderstandings.

Detailed shop drawings also help contractors follow building codes and safety rules. When everything is drawn out clearly, it is easier to meet legal and quality standards.

In short, shop drawings save time, reduce errors, and help deliver a better final product. For contractors, they are not just drawings—they are guides that lead to successful projects.

The Impact of Technology on Shop Drawings

Technology has changed the way shop drawings are made and used in construction. In the past, shop drawings were made by hand. This process was slow and sometimes led to mistakes. Today, with the help of computers and software, shop drawings are faster to create and much more accurate.

CAD (Computer-Aided Design) and BIM (Building Information Modeling) are two common tools used now. These tools help drafters make detailed and clear drawings. They also allow easy updates if changes are needed. This saves time and reduces errors on the job site.

3D modeling is another big improvement. It helps designers, builders, and clients see how the final product will look. This improves communication and helps avoid confusion. Everyone involved can better understand the project before it even starts.

Technology also helps teams work together, even if they are in different places. Cloud-based platforms allow people to share and review shop drawings in real time. This leads to quicker approvals and smoother workflows.

In short, technology has made shop drawings better, faster, and more reliable. It helps reduce mistakes, saves money, and improves teamwork. As new tools continue to develop, the process of creating shop drawings will only get better.

Best Practices for Contractors Working with Shop Drawings

Shop drawings are detailed plans that show how parts of a project will be built. For contractors, working with shop drawings properly is very important to avoid mistakes and delays. Here are some best practices:

1. Review Carefully:

Always take time to review shop drawings carefully. Make sure they match the project plans and specifications. Look for any differences or errors that could cause problems during construction.

2. Communicate with the Team:

Talk to the architect, engineer, or designer if something is not clear. Good communication helps avoid confusion and ensures that everyone is on the same page.

3. Stay Organized:

Keep all shop drawings well-organized and easy to access. Use folders or digital tools to manage different versions. This helps you work faster and reduces the chance of using outdated drawings.

4. Approve on Time:

Don’t delay in giving your approval or feedback. Late responses can hold up the work and affect the overall timeline.

5. Follow the Drawing During Construction:

Make sure the work on site follows the approved shop drawings. If changes happen, update the drawings and share them with the team.

6. Use Checklists:

Using a checklist when reviewing drawings helps ensure you don’t miss anything important, like measurements, materials, or special instructions.

The End Note

In today’s construction landscape, detailed shop drawings are not just helpful, they’re essential. They serve as the link between design concepts and on-site execution, offering contractors the clarity and precision they need to complete projects efficiently and accurately.

From improving coordination across trades to reducing costly errors and delays, shop drawings play a pivotal role in every phase of construction. The integration of modern technology like CAD, BIM, and cloud-based tools has further elevated their value, enabling faster revisions, better communication, and enhanced project outcomes.

By following best practices such as thorough reviews, timely approvals, and clear communication, contractors can ensure that shop drawings serve as a powerful guide toward successful project delivery. Ultimately, investing time and attention into shop drawings leads to smoother workflows, stronger collaboration, and higher quality results on the job site.

- Information Technology

- Office Equipment and Supplies

- Cars and Trucks

- Persons

- Books and Authors

- Tutorials

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Oyunlar

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness